TM 9-6115-624-BD

b.

Personnel/time required.

1 soldier/0.25-1.0 hours

c.

Materials/tools

Tin can

Stiff wire (coat hanger, welding rod)

d.

Procedural Steps.

(1) Gain access to hose.

(2) Drain coolant into container for reuse.

(3) Loosen and remove clamp from one end of the hose.

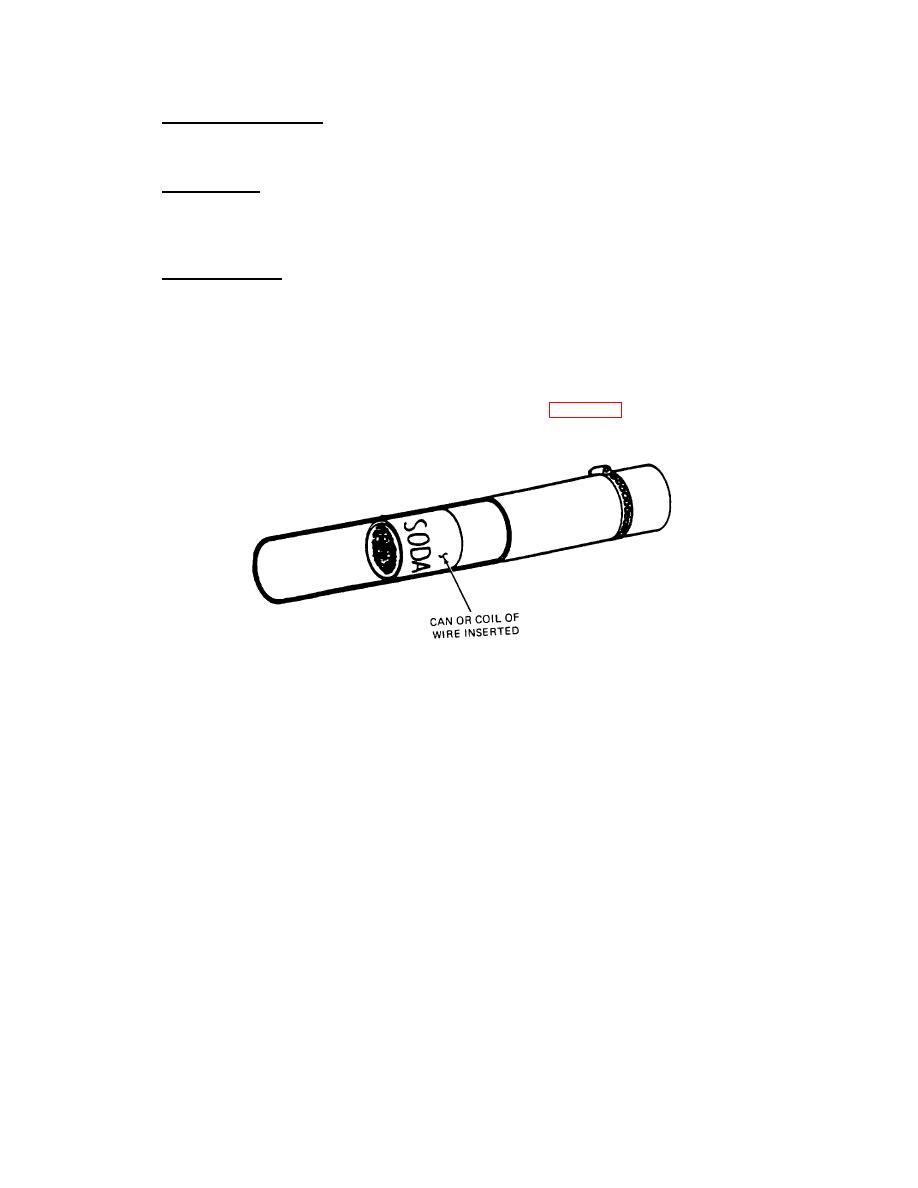

(4) Insert a can with ends removed or bent wire into the hose (figure 6-8).

Figure 6-8. Reinforce Collapsed Hose.

(5)

Reconnect and tighten the hose.

(6)

Refill coolant to proper level.

(7)

Check for leaks.

Record the BDAR action taken. When the mission is completed, as soon as practicable, repair the generator using

standard maintenance procedures.

6-16. Hose Improvisation (Low Pressure). Coolant hose or tube damage will sometimes be such that a patch will not

stop the leak. The damaged portion must be removed and replaced with a substitute. Several repairs can be made

using one of the following procedures.

a.

Limitations.

None

b.

Personnel/time required.

1 soldier/i 5-60 minutes.

6-11