TM 9-6115-624-BD

c.

Materials/tools.

Wire brush

Solvent

Epoxy (item 1 or 3, appx c)

d. Procedural Steps.

(a) Gain access to radiator.

(b) Inspect the radiator and pinpoint the leak location.

(c) Drain the coolant into a container for reuse.

(d) Clean the leak area with solvent or available cleaner.

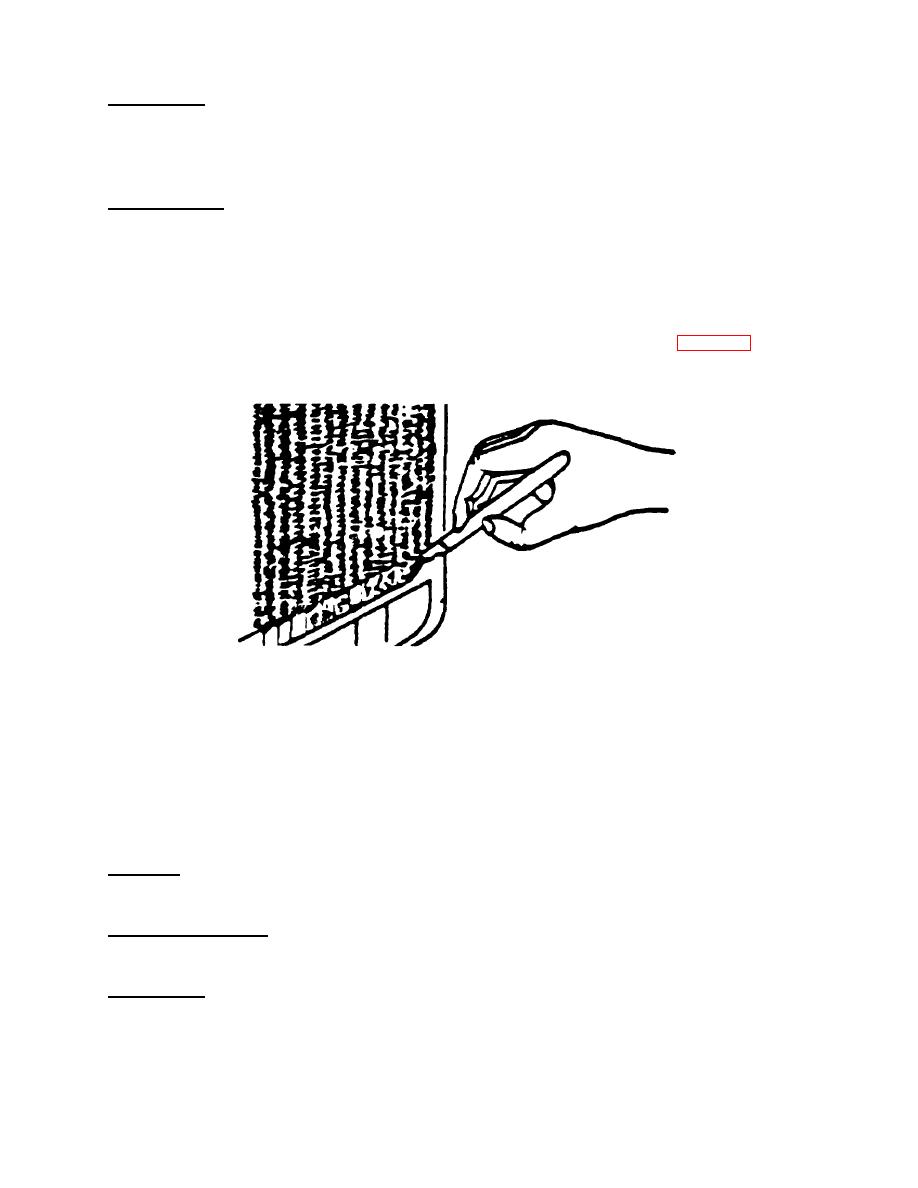

(e) Scrape or rough up the damaged surface with a wire brush or knife as shown (figure 6-3).

(f) Mix epoxy according to kit instructions and fill the hole with the mixture. Work the epoxy well into the

crack.

Figure 6-3. Radiator Hole Epoxy Fix.

(g) Allow epoxy to cure. A heat lamp will speed the curing.

(h) Refill radiator and check for leaks.

(i) Install radiator cap in pressure release position.

Record BDAR action taken. When mission is complete, as soon as practicable, repair the equipment/system using

standard maintenance procedure.

6-12.

Option 3: Core Punctured Repair.

a. Limitations.

Possible reduced cooling.

b. Personnel/time required.

1 soldier/30-60 minutes

c.

Materials/tools.

Side cutters

Sandpaper

Epoxy or solder (item 1, 3, 16, or 17, appx c)

Propane torch or soldering iron

6-6