TM 9-6115-624-BD

(e) Re-enforce the patch with wire or string to distribute the patch sealing pressure evenly over the damaged

area.

(f) Install radiator cap in pressure release position.

(3) Option 3: Hose, large leak.

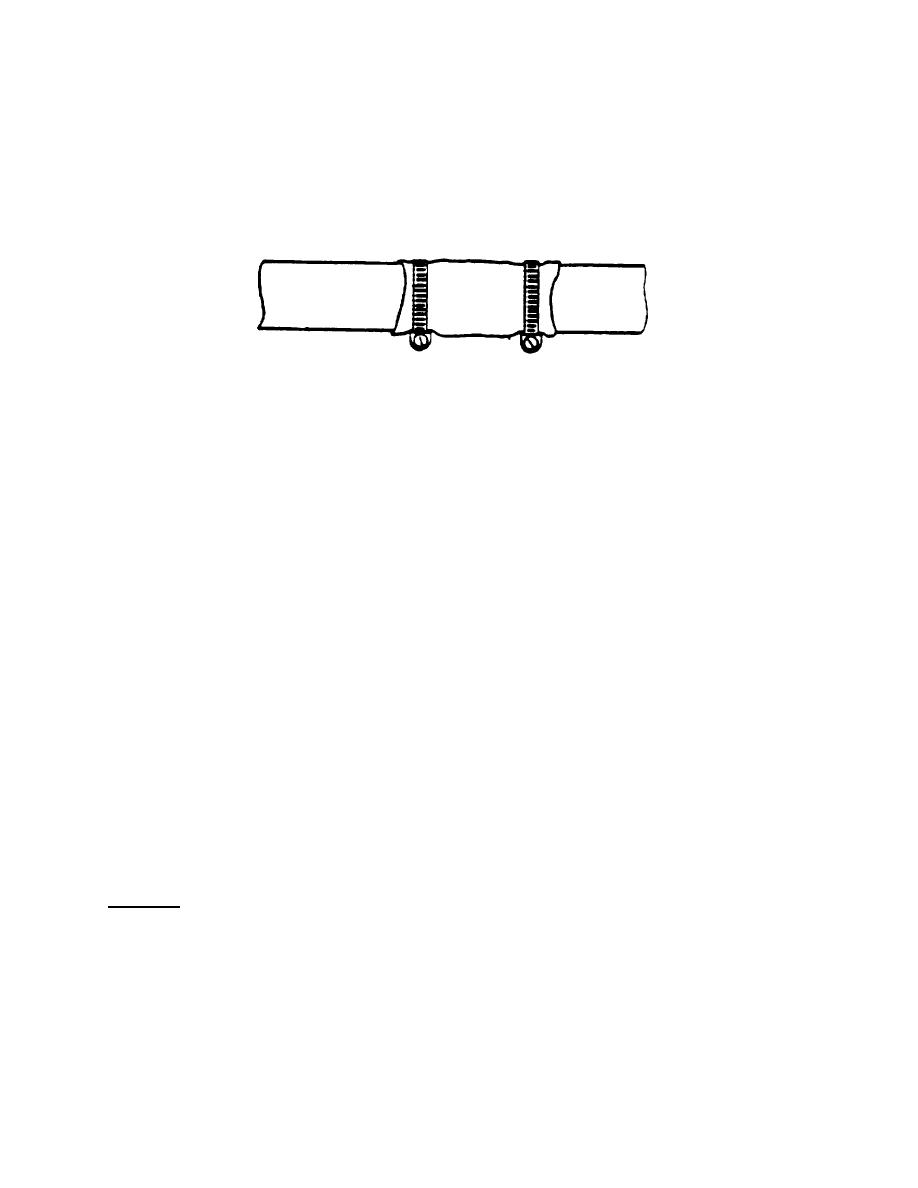

Figure 6-7. Hose, Large Leak.

(b) Clean dirt and oil from damaged area.

(c) Coat the damaged area with gasket sealer.

(d) Cut a metal patch from a tin can or other thin metal.

(e) Bend the metal into a cylindrical shape the size of the damaged hose and coat the inside with sealer.

(f) Wrap the metal patch over the damaged hose.

(g) Secure the patch with adjustable clamps or tape.

(h) Check for leaks.

(i) Install radiator cap in pressure release position.

(4)

Other options: Use a tire patch repair kit.

Record the BDAR action taken. When the mission is completed, as soon as practicable, repair the generator using

standard maintenance procedures.

6-15. Hose, Collapse. When the rubber in the coolant hoses starts to deteriorate it becomes soft and has a spongy

feeling which may result in hose collapse. The hose can be reinforced by inserting a rigid hollow object like a can or wire

coiled to prevent the hose from collapsing. The inserted item will help the hose remain open even though the suction is

trying to close it.

a. Limitations.

None

6-10