TM 9-6115-624-BD

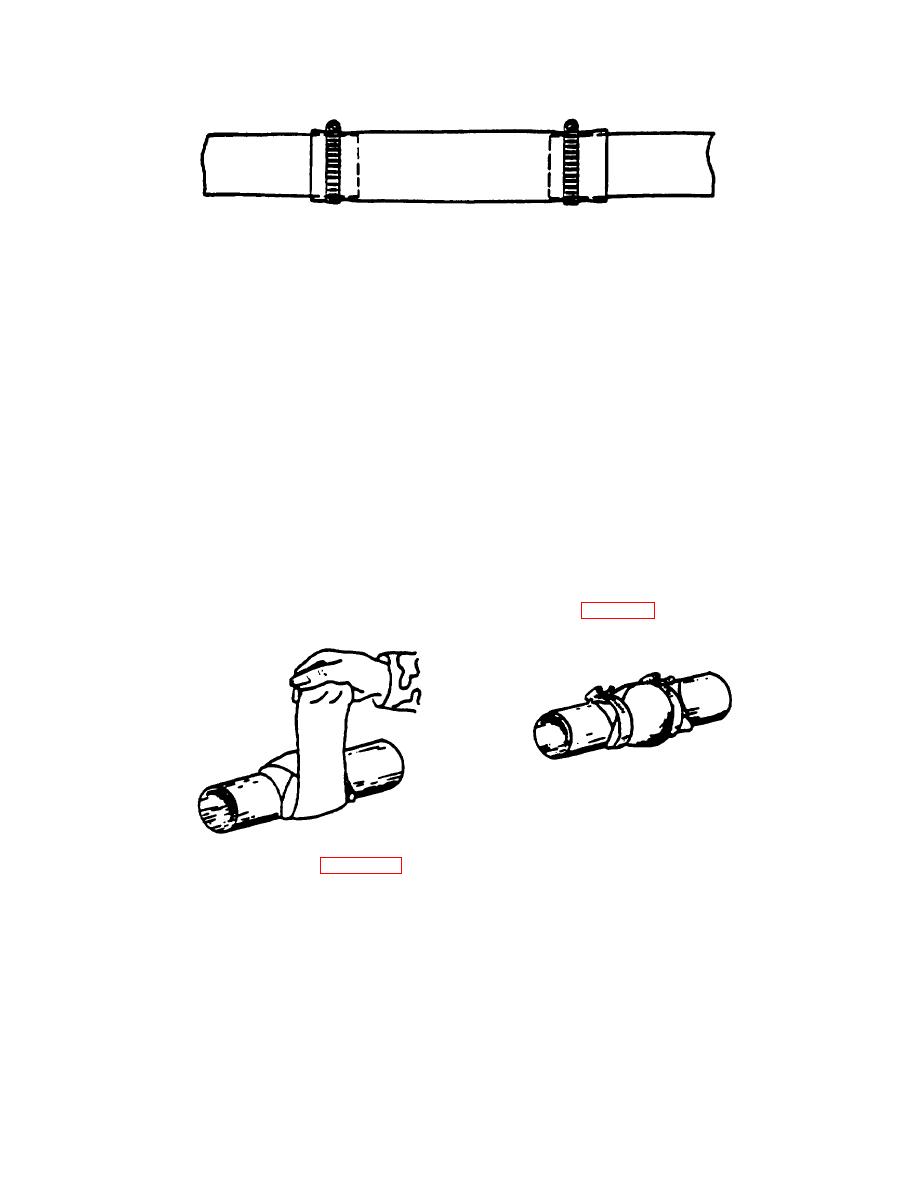

Figure 6-10. Substitute Hose as Sleeve.

(e)

Secure the substitute hose with clamps or twisted wire, do not overtighten and restrict the coolant

flow.

(f)

If the damaged hose inside diameter equals the outside diameter of the substitute hose, the hose

can be inserted into the damaged hose and secured. This, however, will not work with tubing.

(g)

Refill coolant to proper level and check for leaks.

(h)

Install radiator cap in pressure release position.

(3) Option 3: Short hose fabrication.

(a)

Use a short section of innertube, or rubber sheet cut to required length.

(b)

Coat the tubing ends with sealant.

(c)

Slip the material over the tubing ends.

(d)

Wrap the innertube as tightly as possible on the tubing (figure 6-1 1).

(e)

Secure the inntertube using hose clamps or tightly wound wire.

(f)

Refill coolant to proper level and check for leaks.

(g)

Install radiator cap in pressure release position.

Record the BDAR action taken. When the mission is completed, as soon as practicable, repair the generator using

standard maintenance procedures.

6-13/(6-14 blank)