TM 55-6115-491-40

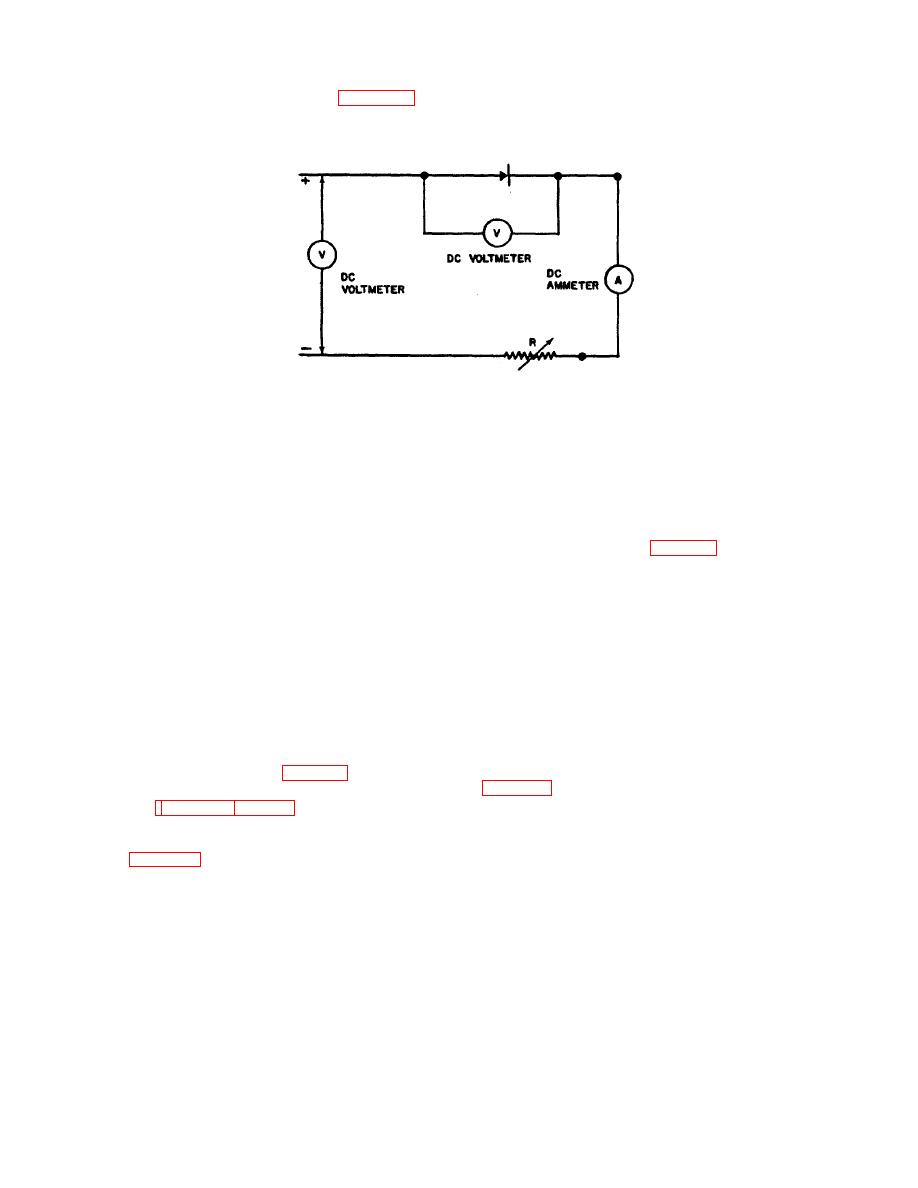

b. Connect the diode as shown in figure 3-5 to

voltage drop across the diode should be less than 1.5

volt DC at 770F (250 C). Replace the diode if it fails to

check forward current flow. Increase the DC input

conform to these requirements.

voltage until the ammeter indicates 3 amps. The

Figure 3-5. Diode Forward Current Test.

b. Position the assembled brush boxes on the

3-29. MODIFICATION CRITERIA.

bearing support (46) and brush holder insulations (37) on

3-30. Comply with the following instructions in order to

the bearing support; secure with the bolts (32), washers

control configuration of generator Part No. 31220-002.

(33), plates (34), insulation (35), and bushing insulator

a. If shaft Part No. 31220-1053 is installed,

(36). Tighten the bolts to 17 to 20 inch-pounds.

and if the letter "S" is already on the identification plate

c. Position the brush holders (25) and brush

following the serial number, obliterate the letter "S".

holder insulations on the bearing support using the

b. If shaft Part No. 31220-1160 is installed,

aligning tool indicated in table 2-2. Secure by installing

assure that the letter "S" is stamped on the identification

the bolts (26), washers (27), plates (28), insulations (29),

plate following the numerical serial number.

and bushing insulator (30). Tighten the bolts to 17 to 20

c. If bearing Part No. 07-111424 is replaced

inch-pounds.

with bearing Part No. 07-111438 and if the letter "B" is

d. Install the electrical leads (17 through 19)

not already on the identification plate after the serial

and the wire jumper (20) that interconnect the brush

number, stamp the letter "B" onto the plate.

holders.

d. If it is necessary to install bearings Part No.

e. Position the exciter board (8), spacer

07-11424 due to the non-availability of bearing Part No.

gasket (15), and standoff insulator (16) on the bearing

07-111438, and if the letter "B" is already on the

support (46); secure by installing the terminal sleeves

identification plate, either replace the identification plate

(14), insulator bushings (13), flat washers (12), bolts

or obliterate the letter "B" from the present plate.

(11), washers (10), and nuts (9). The terminal board

3-31. LUBRICATION.

must be positioned so that A- faces the anti-drive end.

3-32. Lubricate the parts of the generator prior to

f.

If they were removed, install new studs (70,

reassembly using items 2 and 3 of table 2-3.

3-33. REASSEMBLY.

(69) that were removed from the terminal board (71).

3-34. Refer to figures 3-1 and 3-2 and reassemble the

g. Position the assembled brush support

generator as follows:

assembly (661 on the stator housing (74). Connect the

a. Assemble the brush boxes (items 39

exciter terminal board leads. Connect the DC stator

through 45, figure 3-2).

leads to the brush holder. Secure with eight nuts (67)

and washers (68).

3-16