TM 11-6125-240-34

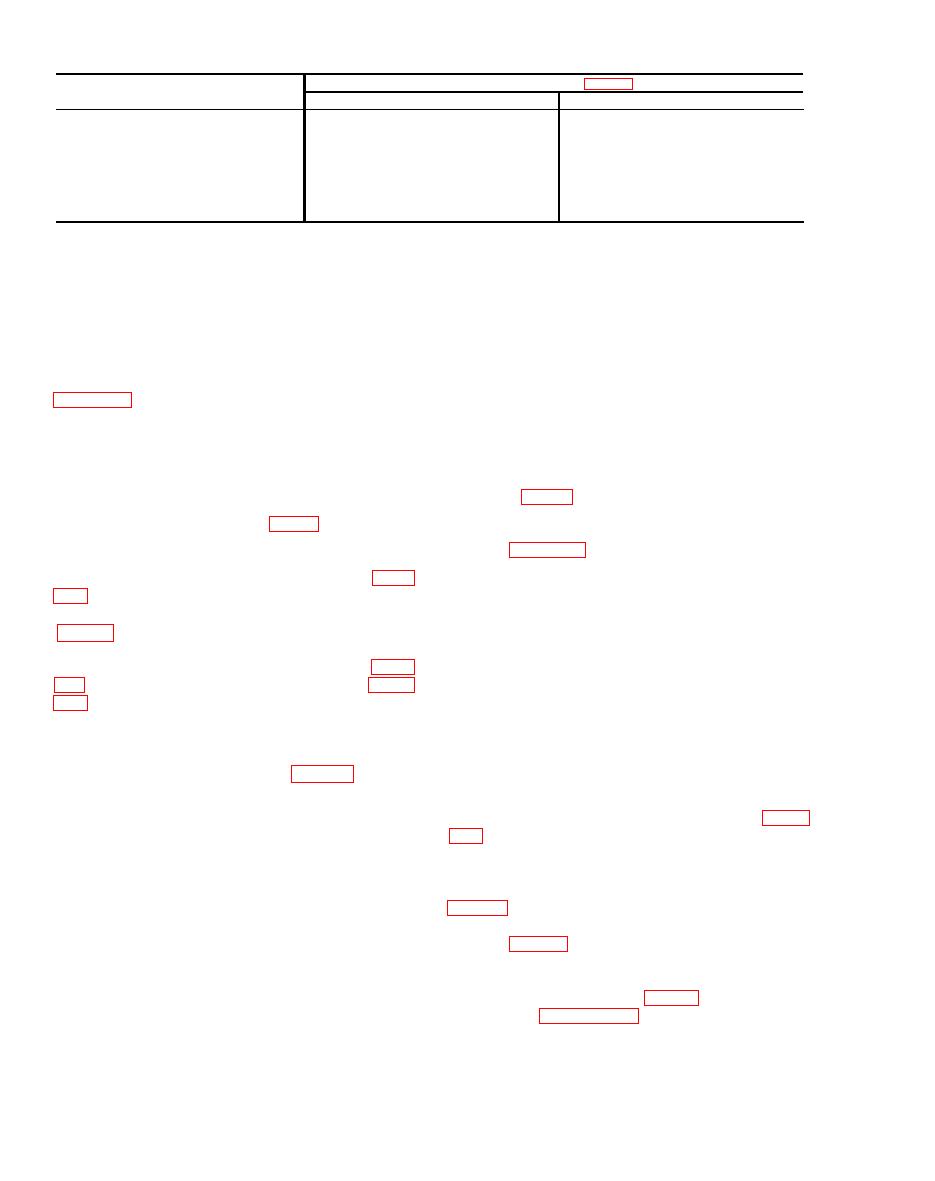

Lead dimensions (B, fig. 4-13)

Dimension A

Reference designation

Dimension B

R6

0.6

0.250

R7

0.9

0.296

R8 thru R22

0.6

0.250

R24

0.6

0.250

R25

0.9

0.296

R26

0.8

0.265

R27

0.8

0.265

CAUTION

(clear), London Chemical Co., Melrose Park, Ill., or

Place soldering iron in contact with lead wire

equivalent.

or circuit board track. Solder must be melted

CAUTION

by heat received from lead wire or circuit

Restrict application of the flux remover only

board track, not by direct contact with solder-

to areas necessary to remove flux, because

ing iron. Do not overheat printed circuit

t h i s cleaning agent deteriorates the

board.

polyurethane coating.

(5) Cut rigid vertical leads of parts, if necessary,

(3) Thoroughly mix polyurethane EN-4 Part A

under circuit board to 1/16 1/32 inch, as shown in C,

(straw) and Part B (amber) with a metal mixing paddle

(100 parts A-17.5 parts B by weight). Dilute with a

CAUTION

50/50 blend of methyl ketone and toluene.

When removing or installing soldered leads of

(4) Brush a thin coating on the component and

resistors, capacitors, transistors, and semi-

cure for 8 hours at 82 C (180 F).

conductor devices, a vacuum soldering method

4-19. Replacement of Regulator Section

must be used to prevent solder from entering

part.

(6) Polarized capacitors C2 (fig. 4-2 and 4-12), C3

through the holes in the regulator housing (54) as

(16), C4 (23), C6 (16), C7 (30) and C8 (15) must be as-

shown in figure 4-14. Be sure ventilation duct (56) is in

sembled to the printed wiring board (44) with the posi-

place.

tive ( + ) lead of the capacitor located as shown in figure

b. Secure the regulator housing with four screws (52

and 53). Attach bracket (51 ), using two screws (49), two

(7) All semiconductor diodes CR1, CR3, CR4, CR9

screws (48), and four flat washers (50).

CR11 (28) must be assembled to the printed wiring

secure to housing with three screws (43) and flat

board with the cathode lead located as shown in figure

washers (44); secure to front of regulator housing with

four screws (45), lockwashers (46), and flat washers

(47). Connect the A, B, C, D, and F leads from the

(8) After soldering, clean joints thoroughly with

generator section to their respective terminals on the

Lonco Flux Remover (HCR) within 4 hours after

back of the filter FL1. Also reconnect loose electrical

soldering operation.

lead to terminal A.

(9) Install transistors Q6, Q11 (fig. 4-2) and tran-

d. Replace terminal board TB3 (41) and secure with

sistor heatsinks (5) to printed wiring board (44) and

four screws (39) and flat washers (40). Replace ter-

secure with screws (2), flat washers (3) and nut and

minal links (18 and 19) in position shown in figure

lockwashers (4). Tighten nut and lockwashers (4) to a

torque of 5 to 6 pound-inches.

e. Replace shouldered stud (29), using lockwasher

(10) After assembling all components to the

(30), and flat washer (31). Slip insulated sleeving (28)

printed wiring board, apply conformal coating of

over stud, and wrap the long lead of capacitor C2 (22,

polyurethane EN-4 as described in b below. Apply

coating to both sides with the exception of those areas

forms choke L10.) Attach the leads to the terminals of

surrounding the mounting holes.

TB1 (12, fig. 4-6) using two bolts (23) four flat washers

b. Protective Polyurethane Coating of Voltage and

(22), one above and one below on each bolt, two lock-

Frequency Regulator 4B93-1-A.

washers (21 ) and two nuts (20). Be sure to engage lug

(1) Clean the component mounting area of the

terminal of capacitor Cl (15, fig. 4-6).

printed circuit board with denatured alcohol to be sure

of satisfactory adhesion of the coating to the board.

card assembly replacement, and then position circuit

(2) Clean the component soldered joints of the

card assembly (38) in regulator housing and secure

printed circuit board with Lonco Flux Remove HCR

with four bolts (36), and flat washers (37). Reattach

4-26