TM 11-6125-240-34

4-20. Setting Brush Neutral

(1) DC AMMETER RANGE to START.

Any time the dc endbell is separated from the stator

(2) AC AMMETER RANGE to 50.

housing, the dc brush neutral position must be reset.

(3) LOAD CONTROL to 0.

Proceed as follows:

(4) DC POWER to ON.

a. Loosen the through-bolts that secure the endbells

(5) LIVE CIRCUITS switch to ON.

to the stator housing just enough to allow some play in

f. After a 10-minute warmup period, rotate dc

he dc endbell.

endbell while observing indication on de AMPS meter

b. Be sure that all toggle switches on the motor-

of test set. A minimum deflection indicates correct

generator test set are in the OFF position, and connect

position.

equipment as shown in figure 3-3.

g. Secure the dc endbell by tightening the through-

c. Adjust power supply to 28 vdc.

bolts. Check to see that meter deflection is still at

d. Zero all test set meters, if necessary.

minimum.

e. Set the test controls as follows:

h. Shut off power, and disconnect equipment.

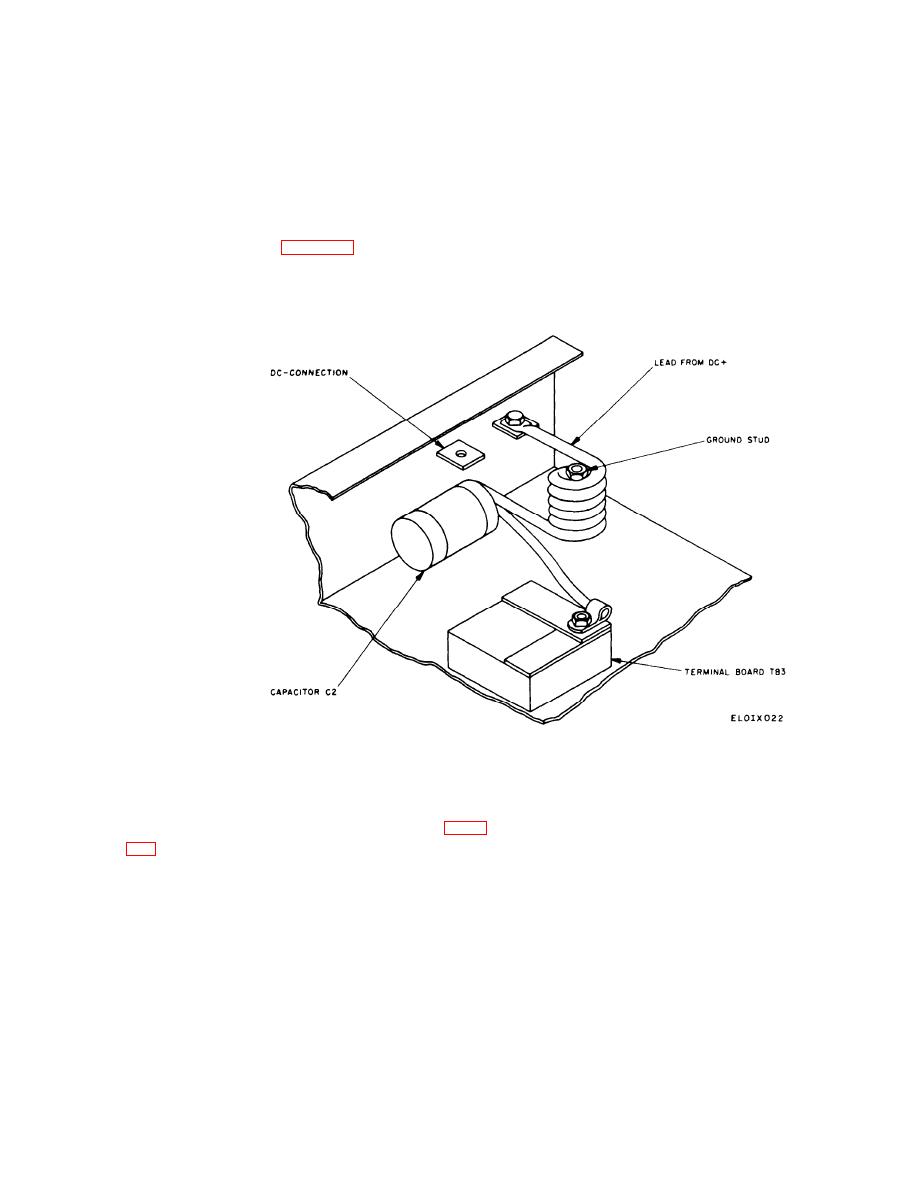

Figure 4-15. Choke Coil Construction.

Section IV. GENERAL SUPPORT TESTING PROCEDURES

4-22. Modification Work Orders (MWO's)

4-21. General

At the time of this publication, there were no MWO's

The direct support testing procedures outlined in tables

pertaining to this equipment. However, inverters, as

they are received, are being modified at depot level to

v e r t e r s which meet the performance standards

accept the 4B93-1-A regulator. These units can be

specified in these tables may be considered acceptable

identified by the letter "M" stamped on the data plate.

For a listing of recent MWO's, refer to DA Pam 310-7.

for return to service.

4-29