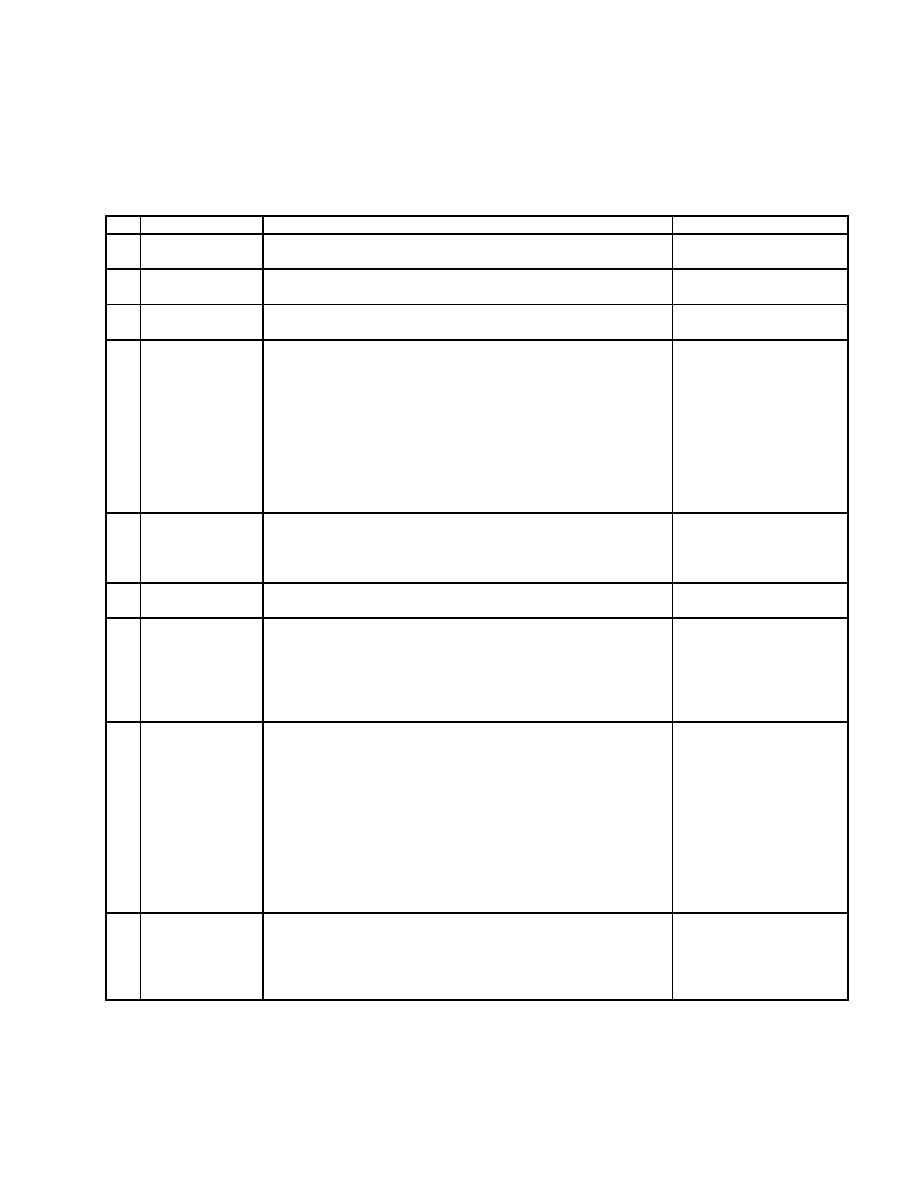

TB 11-6115-741-24

TRAILER INSPECTION CHECKLIST

COMPONENT

REQUIREMENT

CONDITION

1

Air Hose Assembly Will be free of leaks or damage. Minor weather checking on hoses

is acceptable. Air filter assemblies will function properly.

2

Air/Hydraulic

Repair kits will be installed 100 percent for units that do not

Chambers

require replacement.

3

Air Reservoir

Will be free of leaks, damage or corrosion that would weaken the

reservoir.

4

Axles and

Wheel bearings will be greased and adjusted properly. Springs

Suspension

will be free of cracked or broken leaves, excessive worn bushings,

and will show no indication of a permanent set. Spring mounting

hardware will be in place and free of damage. Axle tubes will be

free of breaks and cracks; radius rods will be straight and rubber

bushings will be serviceable. Shock absorbers will be properly

mounted and serviceable. Weather checked rubber grommets are

acceptable. Axle spindle threads will be free of wear, cross threads

or damage. Axle spindles will be free of bends and damaged

bearing seats.

5

Brake System

The operational components of the brake system will be

completely inspected to insure reliability. Brake systems utilizing

polyglycol brake fluid will be converted to silicone brake fluid in

accordance with TB 43-0002-87.

6

Hand Brakes.

The hand or parking brake will be complete with all linkage in a

serviceable condition and properly adjusted.

7

Service Brakes.

Service brakes will be inspected by removing the brake drums.

Brake lining will be properly secured and have a minimum of 50

percent of original thickness remaining above rivet head or 50

percent of original thickness if bonded. Lining will show no

evidence of oil or grease. Brake backing plates and related parts

will be properly mounted, free of bends and distortion.

8

Brake Drums.

Brake drums will not be cracked or distorted. Scores on drum

braking surfaces that reduce lining-to-drum contact more than 10

percent are not acceptable. Refinished drums that are machined to

maximum allowable diameter are acceptable if remaining scores

do not exceed 1/32 inch in width or 1/64 inch in depth. Oversize

will be stamped on outer face of drum just above and between two

studs on finished drums. Linings will not be shimmed. New shoe

and lining assemblies, if required, will be used on both brakes of

the same axle, using the same brake lining composition. Drums

must be matched per axle and will be checked and serviced in

accordance with the applicable TM.

9

Brake Cylinders. Master and brake cylinders will be inspected to insure reliability.

Cylinders will be clean, free of leaks or seepage, properly mounted

and operate freely under pressure. Boots and dust covers are

acceptable with minor weather checks. Evidence of swelling from

oil, grease or hydraulic fluid is not acceptable.