ARMY TM 9-6115-673-13&P

AIR FORCE TO 35C2-3-512-1

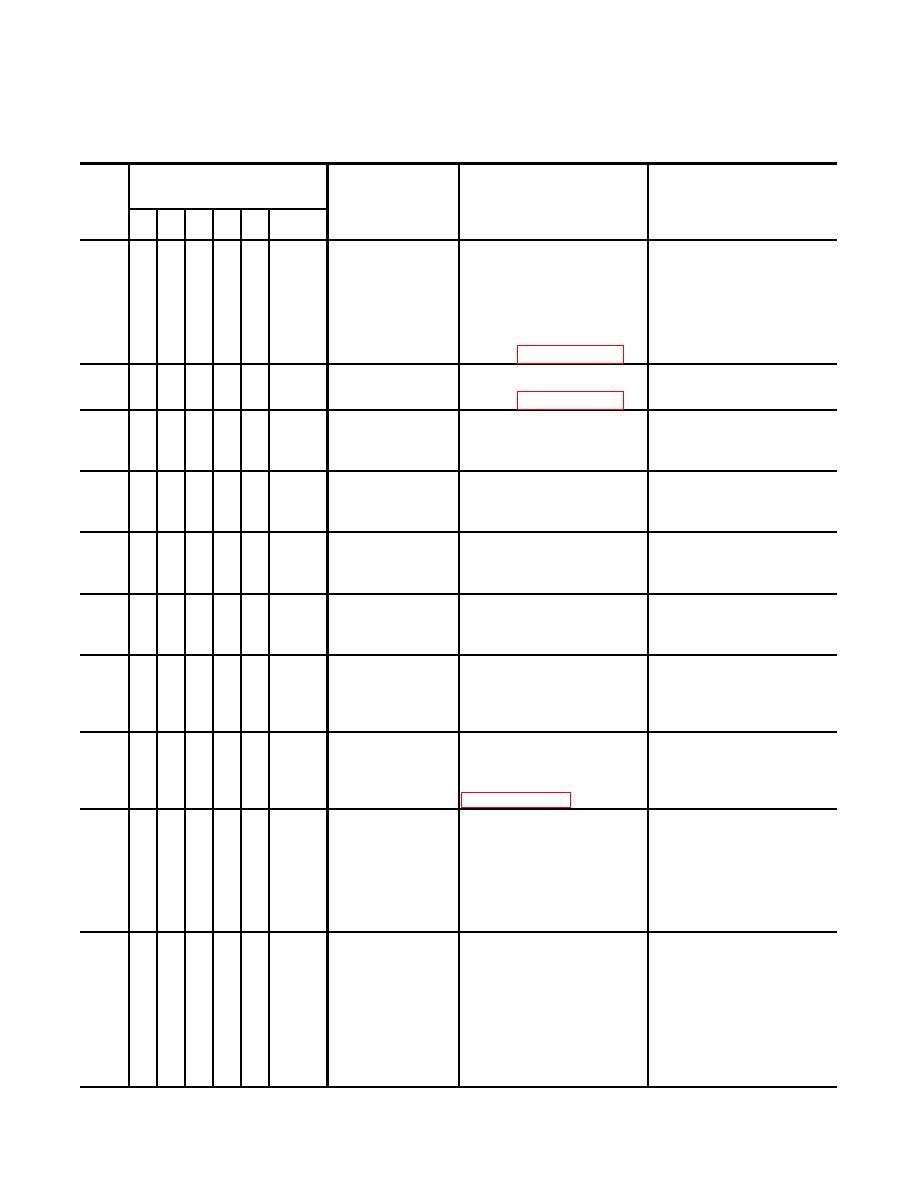

Table 4-1. Unit Preventive Maintenance Checks and Services (Continued)

M-Monthly

Q-Quarterly

S-Semi-annually

A-Annually

B-Bi-annually

H-Hourly

(1)

(2)

(3)

(4)

(5)

Interval

Item

Item To Be

Equipment Is Not

M

Q

S

A

B

H

No.

Inspected

Procedure

Ready/Available If:

(11)

20

Cylinder Head Nuts

Check after first 20 hours of

Head nuts are loose.

operation and then every 500

(1st

hours.

time)

Check for loose head nuts.

500

Torque cylinder head nuts.

Refer to paragraph 4.12.9.

(12)

1000

Fuel Injector

Replace every 1,000 hours.

Refer to paragraph 4.12.3.

(13)

1500

DC Alternator

Contact next higher level of

Brush Holder

maintenance to replace

brush holder assembly.

(14)

2000

Fuel Injection Pump Contact next higher level of

maintenance to replace fuel

injection pump.

(15)

Generator Set,

Check for damage, corrosion, Damaged, corroded, missing,

Engine/Alternator,

missing, or loose attaching

or loose hardware.

and Control Panel

hardware.

(16)

Fuel Lines

Inspect for breaks and/or

Fuel lines leak or show signs

damage. Replace damaged

of wear or damage.

fuel lines.

(17)

Fuel Tank

Check for damaged,

Damaged, corroded, or

corroded, or missing fuel fill

missing components.

strainer, tank cap lug, and

retaining rope.

(18)

Check for damaged flexible

Damaged alternator coupling

(MEP-501A)

sleeve coupling and flexible

components.

flange couplings. Refer to

(19)

Control Panel

Check for damaged,

Damaged, corroded, or

(External)

corroded, or missing

missing control panel

convenience receptacle and

components.

cover (MEP-531A); LOP

engine shutdown cable

grommet and cable guide;

and slave receptacle.

Check for damaged terminal Damaged control panel

(20)

Control Panel

components.

(Internal)

board jumper (MEP-531A)

and ground straps, and

damaged or burned wires

and insulation on all electrical

leads and harnesses.

Ensure that protective cover

on rear of instrument panel is

secure.