ARMY TM 9-6115-639-13

AIR FORCE TO 35C2-3-386-51

MARINE CORPS TM 10155A-13/1

Table 2-1. Operator Preventive Maintenance Checks and Services for MEP 831A / 832A (continued)

Item

No.

Interval

Location:

Item to

Check/

Service

Procedure

Not Fully Mission

Capable If:

13

Before

A8

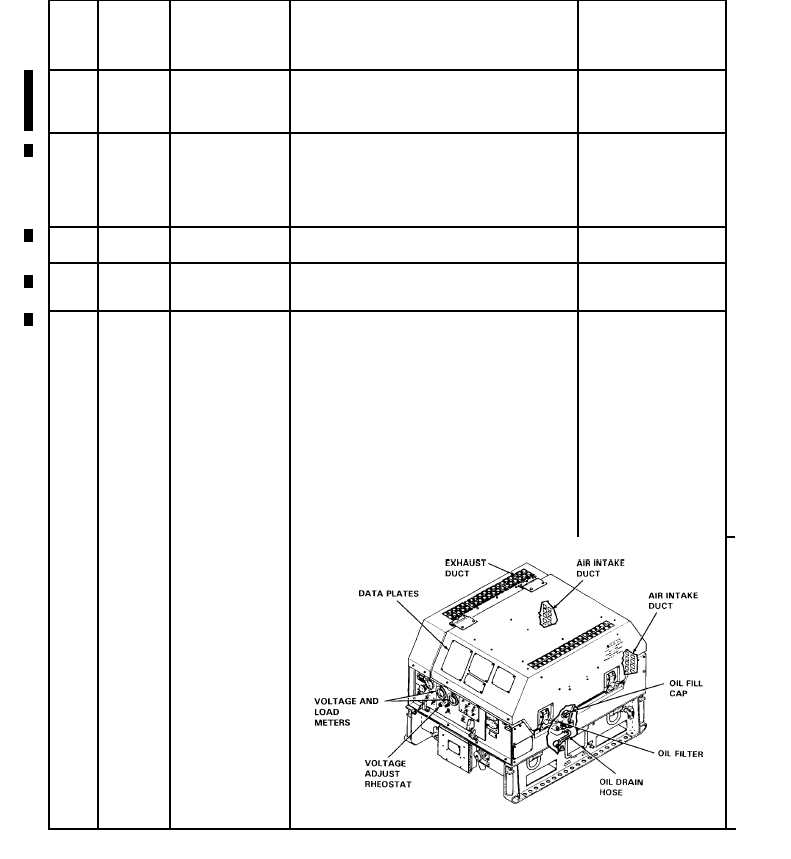

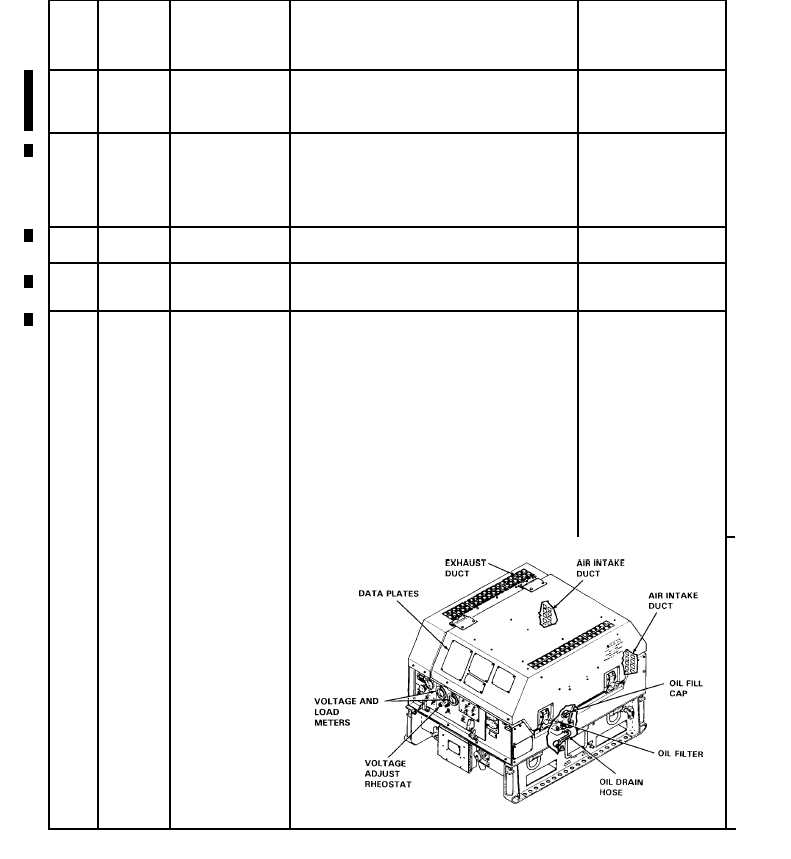

Open enclosure cover. Inspect A8 and area

around A8 for signs of water. If water is

present, thoroughly dry out A8 before starting

generator.

Water is in A8

14

Before

Engine oil

a. Open enclosure cover. Remove oil fill cap

and check oil level. If servicing is

required, refer to para. 3-1.

b. Inspect areas around oil filter and oil drain

hose for leaks.

Class III oil leaks are

present. Refer to

leakage class defini-

tions (para. 2-5).

15

Before

Engine air filter

Inspect air filter for clogging in accordance

with para. 3-9.

Filter is clogged.

16

During

VOLTAGE and

LOAD meters

(control panel)

Monitor output levels during generator set

operation. Adjust output as required using

VOLTAGE ADJUST rheostat.

Adjustments cannot

be made.

17

During

FUEL LEVEL

Meter (located on

control panel)

a. Monitor fuel level during generator set

operation.

WARNING:

Never service generator set while engine is

running. Shut down unit before filling with

fuel. Injury to personnel can occur if proper

procedures are not followed.

b. Replenish fuel as follows: Shut down

generator set. Remove fuel fill cap and

fill with proper fuel. Install fuel fill cap.

Fuel level is empty or

level meter is

inoperable.

2-16

Change 1