ARMY TM 9-6115-639-13

AIR FORCE TO 35C2-3-386-51

MARINE CORPS TM 10155A-13/1

Table 2-1. Operator Preventive Maintenance Checks and Services for MEP 831A / 832A

Item

No.

Interval

Location:

Item to

Check/

Service

Procedure

Not Fully Mission

Capable If:

1

Before

Overall generator

set

a. Inspect for cracks, dents, and corrosion

in accordance with para. 3-5.

b. Inspect for loose or missing hardware.

Significant cracks in

any generator set

component.

2

Before

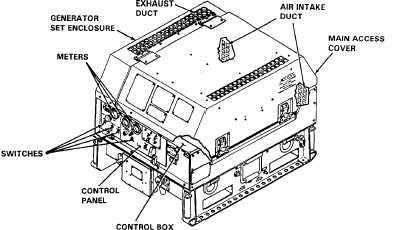

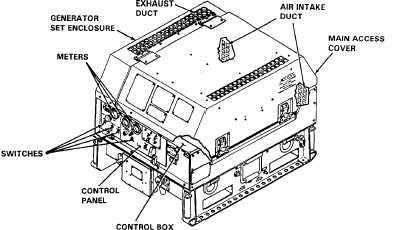

Generator set

enclosure

a. Inspect top lifting cover for security of

attachment in accordance with para. 3-5.

b. Inspect air intake and exhaust ducts for

obstructions and blockages. Clear

obstructions and check for damage.

Cover is not secure.

Latches do not lock,

allowing cover to

rattle excessively.

Intake or exhaust are

blocked, or damaged.

3

Before

Control box and

output panel

a. Inspect for secure attachment. Check that

hinged panel is closed and locked.

b. Inspect switches, meters, indicators, and

terminals. Conduct fault lamp test by

depressing FAULT RESET / PUSH TEST

switch. Refer to para. 3-6.

c. Inspect electrical wires for damage, corr-

osion, or electrical short. Check for bent,

broken, or missing pins.

Any switch is not

operable or any meter

is damaged. Fault

indicator is defective

or lamp does not light.

Wires or connectors

are damaged.

2-12

Change 1