TM 55-61115-498-40

inches, when measured with an air gage, air

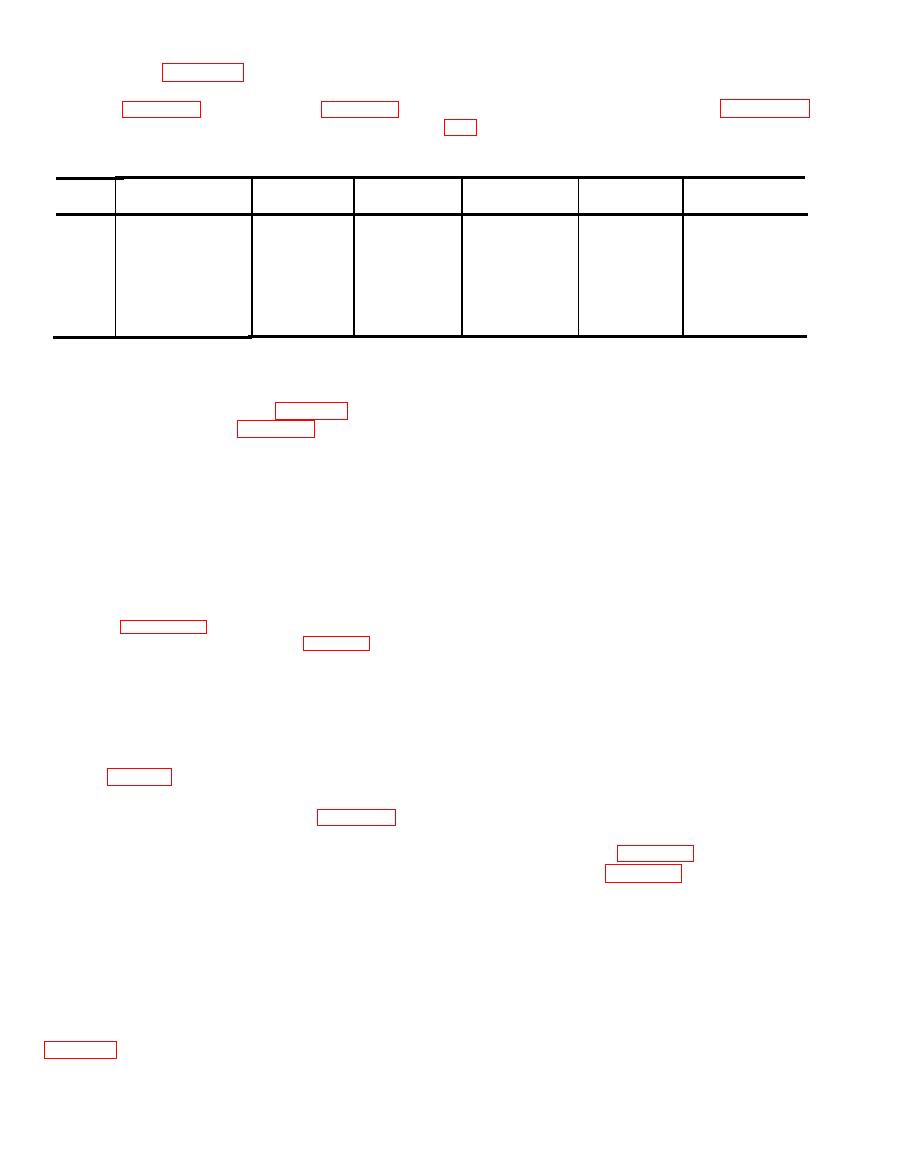

Refer to table 3-2 for fits and clearances

d.

probe, and a 2.0475-inch setting ring, metallize

of component parts. If the inside diameter end

the worn surface as described in paragraph

bell (34, figure 3-2) or stator (22, figure 3-3)

of housing bearing bone is worn beyond 2.0475

Table 3-2. Fits and Clearances

Service

Service

Service

Mating

dimensions

tolerance

parts

dimensions

Part No.

(inches)

(inches)

part No.

Nomenclature

(inches)

Nomenclature

0.9843 ID

0.0000 L/L

890659-5

Ball Bearing

1544645

0.9843 OD

Armature Assy

shaft bearing

surfaces)

2.0470 OD

0.0005 L

890659-5

Ball Bearing

2.0475 ID

154443-1

End Bell (bear-

ing bore)

2.0470 OD

Ball Bearing

0.0005 L

2.0475 ID

8906595

Stator Housing

1544457

(bearing bore)

placing the steam nozzle of steam dispenser

3-3. CLEANING.

(table 3) in the mixing tank.

with trichlorethylene (item 1, table 2-3) or dry

NOTE

cleaning solvent (item 2, table 2-3 ). Do not dip

The strength of the solution can be varied to

pants into the solvent. Use a stiff, nylon brush

suit conditions.

to scrub the parts throughly,

(2) Use approximately 140 psi of steam and

regulate the pressure at the boiler rather than at

WARNING

the nozzle to avoid pressurizing the hose line.

Use solvent in a well-ventilated area.

(3) Using a spray booth with adequate

Avoid inhaling solvent fumes. Do not al-

ventilation and exhaust fans, thoroughly clean

low solvent to contact the skin as burns

the genenator stator and armature assembly with

may occur.

the mixture of steam and detergent until all

NOTE

caked grease and carbon are removed. The pro-

portion of detergent to steam can be varied de-

pending upon the condition of Ithe generator

cedures for armature assembly (45, figure 3-1)

and generator Water (48).

stator and armature assembly.

(4) Shut off the detergent and continue

(1) Ultrasonic cleaning equipment may be

used, if available. Consult the manufacturer of

blasting with steam until all traces of detergent

this equipment for proper cleaning solutions

are removed.

and methods to be used.

(5) With an oven capable of maintaining

(2) Dry parts with a clean, lint-free cloth

149 C (300F), bake the generator stator and

(item 3, table 2-3).

armature assembly at 121 C (250 F) for 4

b. Armature Assembly and Generator Stator.

hours to thoroughly dry the parts.

Steam clean armature assembly (45, figure 3-1 )

(6) After baking, apply a light film of

and enerator stator (48) `to remove any carbon,

lubricating oil (item 5, table 2-3 ) or corrosion

copper particles embedded, or any other foreign

matter between the commutator bars and stator

preventive (item 6, table 2-3 ) to all ferrous

windings, as described in following steps (1)

metal surfaces to prevent rusting.

through (6).

CAUTION

WARNING

Do not apply oil to the commutator sur-

Goggles, rubber gloves, and other pro-

face.

tective clothing should be worn.

3-4. REPAIR OR REPLACEMENT.

(1) Prepare a quantity of detergent, using

approximately 7 1/2 pounds of cleaner (item 4,

NOTE

Paragraphs b through f below list and describe

should be heated and thoroughly agitated by

procedures for repairable parts only.