TM 55-6115-498-40

to remove all traces of rosin and other foreign

(4) Insert the end bell or stator housing in

matter.

a lathe, and rotate it at a speed of approximately

f. Sleeving Replacement. If it is necessary to

60 rpm.

replace sleeving on capacitor leads, use vinyl-flex

CAUTION

fiberglass tubing. The sleeving replacement.

should have a black color, an inside diameter of

The area to be metallized must be abso-

between 0.040 inch and 0.049 inch, and a length

lutely clean.

of 1 3/4 inches.

(5) To prevent condensation of moisture,

make several rapid passes over the work with

3-5. LUBRICATION.

the flame only, immediately before applying the

molybdenum c o a t i n g ( i t e m 1 7 , t a b l e 2 - 3 ) .

The only lubrication required for the dc gen-

Should the bore be so impregnated with grease

erator is after assembly, coat the drive shaft

as to prevent metallizing, replace the end bell

spline with a light film of spline lubricant (item

or stator housing.

11, table 2-3). If this lubricant is not available,

(6) Make several passes over the bearing

use high-temperature lubricating grease (item

bore to deposit a thin coat of molybdenum.

12, table 2-3)

(7) Complete the metallizing with molyb-

NOTE

denum or 0.80 percent carbon steel wire to a

Use of sealing compounds is specified through-

thickness of 0.006 inch on top of the finished

out the reassembly paragraphs.

diameter (finished diameter minus 0.012 inch).

(8) Rough bore the surface to 0.010 inch

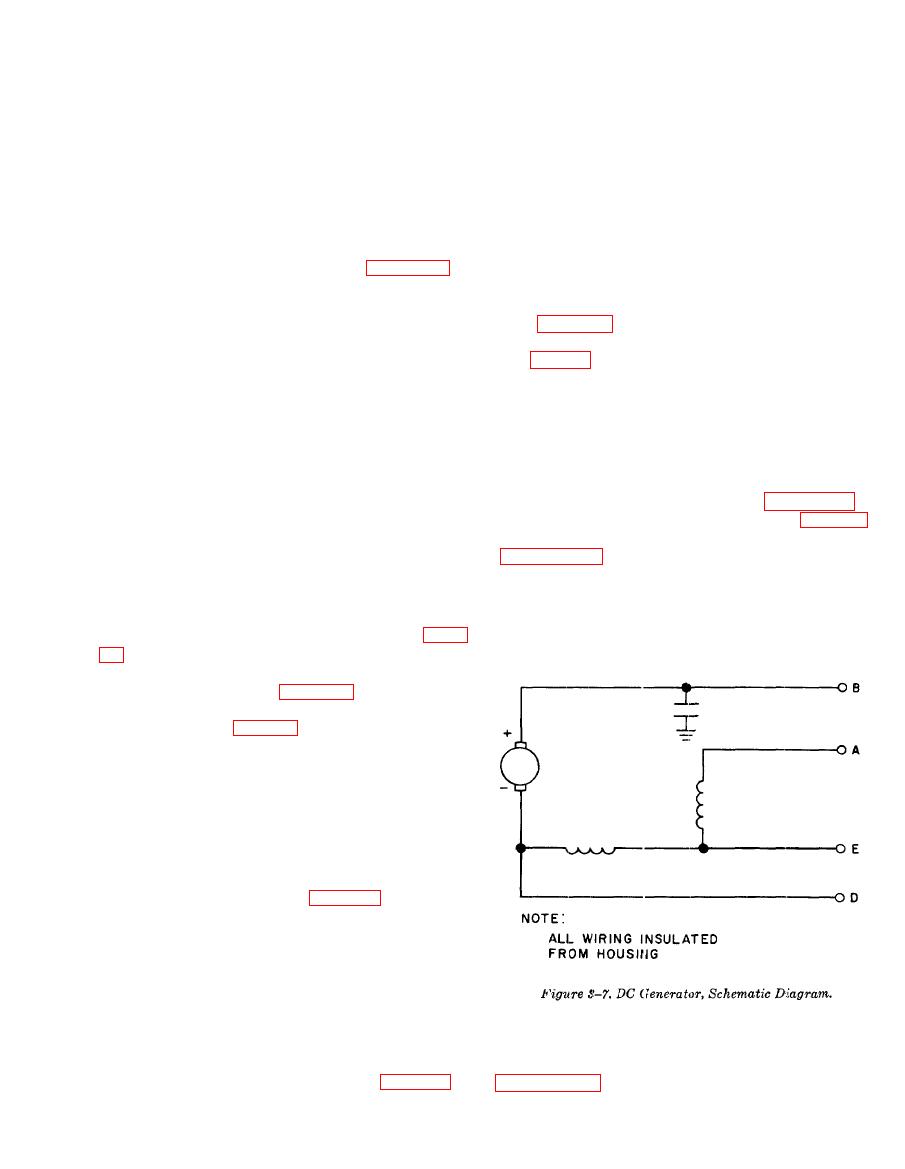

3-6. REASSEMBLY.

under the finished diameter. Finish the surface

Reassembly is basically the reverse of disassem-

by grinding to an inside diameter of 2.0472,

bly. Follow the exploded views (figures 3-1,

plus 0.0003, minus 0.0000 inches. The concen-

3-2, and 3-3), the schematic diagram (figure 3-

tricity between the inside diameter of the bearing

7) and the detailed procedures as described in

bore and both the outermost (4.122-inch) di-

ameter of the stator housing, and the largest

structions.

inside (6.125-inch) diameter of the end bell

must be within 0.002 inch, full indicator reading.

(9) Remove masking shellac and grinding

residue with denatured alcohol (item 8, table

2-3) .

e. Soldering.

(1) If terminals (29, figure 3-1) were re-

placed, use a rosin core solder composed of 100

percent tin (item 9, table 2-3) to solder the ter-

minals to the capacitor leads. This solder has a

melting point of 232 C (450 F).

CAUTION

D o not use an acid solder or an acid

flux, Do not burn insulation when sol-

dering.

(2) For all other soldering operations, use

silver brazing alloy (item 10, table 2-3) com-

posed of 15 percent silver, 80 percent copper,

and 5 percent phosphorous. This solder has a

m e l t i n g range between 650 C and 705 C

(1200 F and 1300 F).

(3) All soft soldering must be done in ac-

cordance with Specification MIL-S-6872B. All

silver brazing must be done in accordance with

a. Generator Stator.

Specification MIL-B-7883B.

(1) If any terminals were removed or re-

(4) After soldering or brazing, clean all

placed, braze terminals to leads as specified in

joints with denatured alcohol (item 7, table 2-3)