TM 55-2925-236-40

c. Secure the end bell capacitors in place with

mounting hardware (see figure 3-2).

d. Position the terminal board capacitors as

shown in figure 36.

e. Apply the epoxy mixture with a paddle or

spatula to form a fillet. On the end bell capaci-

tors, cement the capacitors and loop clamps to

the housing. Wipe away all excess material be-

fore curing.

f. Allow the mixture to cure for 24 hours at

room temperature or for 3 hours at 150 F (66

c).

3-11. Lubrication

The only lubrication required for the starter

generator is after assembly, coat the drive shaft

spline with a light film of spline lubricant (item

11, table 2-3). If this lubricant is not available,

use high-temperature lubricating grease (item

12, table 2-3).

Note. Use of sealing compounds is specified

throughout the reassembly paragraphs.

four washers (31), sixteen insulating washers

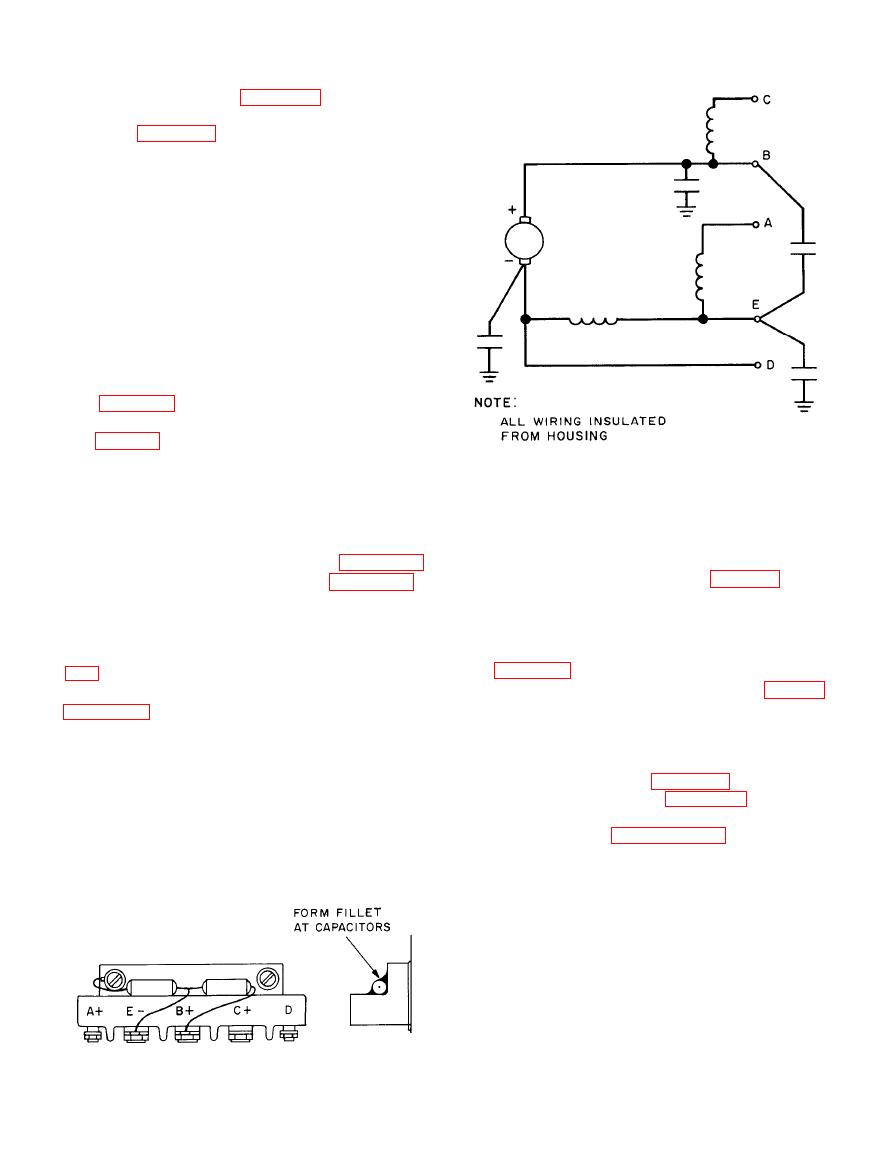

312. Reassembly

(32), and four insulating tubes (33).

(3) Coat the area between the insulating

Reassembly is basically the reverse of disas-

washers and the electrical contact holder bosses

sembly. Follow the exploded views (figures 3-1

with red glyptal lacquer (item 13, table 2-3), and

and 3-2 ), the schematic diagram (figure 37)

tighten screws (29) to a torque of 75 to 80 pound-

and the detailed instructions (paragraphs a and

inches.

b) for reassembly information.

b. Starter Generator.

a. End Bell Assembly.

(1) Mount three terminal board insulators

(1) If capacitors (6, 13, 20, and 27, figure

(53). Apply sealing compound (item 14, table 2-

end bell (34) and cement as described in para-

3) to threads of two screws (50). Secure termi-

nal board (49) to the housing and stator with

Note. Terminals of capacitors (6) will be

two screws (50) and two washers (51), making

secured to electrical contact holders (28) when split-type

sure to install the terminal of capacitor (15) un-

brushes are installed (paragraph b). Terminals of capaci-

der one screw as shown in figure 36.

tors (13, 20, and 27) will be secured to threaded holes in

(2) If capacitors (15, figure 3-1) were re-

heads of screws (29) at final assembly (paragraph b).

moved or replaced, secure them to terminal board

(2) Using brush box aligner (1106006-1)

(49) as described in paragraph 3-10.

and brush box aligner pilor ( 11060051 ), secure

(3) Install identification plate (46) on

electrical contact holders (28) to end bell (34)

housing and secure with four screws (47).

with four screws (29), four lock washers (30),

(4) Mount bearing retainer (45) and one

dirt slinger (43) on the drive end of armature

assembly (39).

(5) Mount bearing retainer (37) and one

dirt slinger (35) on the commutator end of arma-

ture assembly (39).

(6) Stand armature assembly (39) on rotor

stand (1106149). Heat ball bearings (36 and 44)

to 250 F ( 121 C) and install on armature as-

sembly (39), making sure that the dirt slingers

are properly positioned.