TM 55-2925-236-40

a. Test Conditions.

b. Connect `the negative terminal of the bat-

(1) Temperature. Since the starter genera-

tery to terminal E- on the terminal board.

tor is self-cooled, no cooling air is required. Check

c. Apply battery current to the field for 5 sec-

that the ambient temperature is 77 27 F (25

onds by closing the knife switch.

15C).

d. Repeat the operation several times to be

(2) Direction of rotation. Drive the starter

sure that the field is properly flashed.

generator in a counterclockwise direction, as

Caution: Use a knife switch when flashing

viewed from the drive end, during all tests.

the field. Opening the circuit at the starter gen-

(3) Plastic windows. It is recommended that

erator or battery terminals can result in severe

a transparent plastic window strap be used dur-

damage to the terminals or explosion of the bat-

ing the brush seating procedure, so that the com-

tery.

mutator end brushes will be visible. A spare

brush access cover can be modified in the shop

4-3 Brush Seating

by cutting out squares, and riveting transparent

a. Remove the brush access cover and replace

non-flammable plastic window panes in place on

it with the plastic window strap. (Refer to para-

the cover.

Caution: Do not operate the starter gen-

observed.

erator without the brush access cover in place,

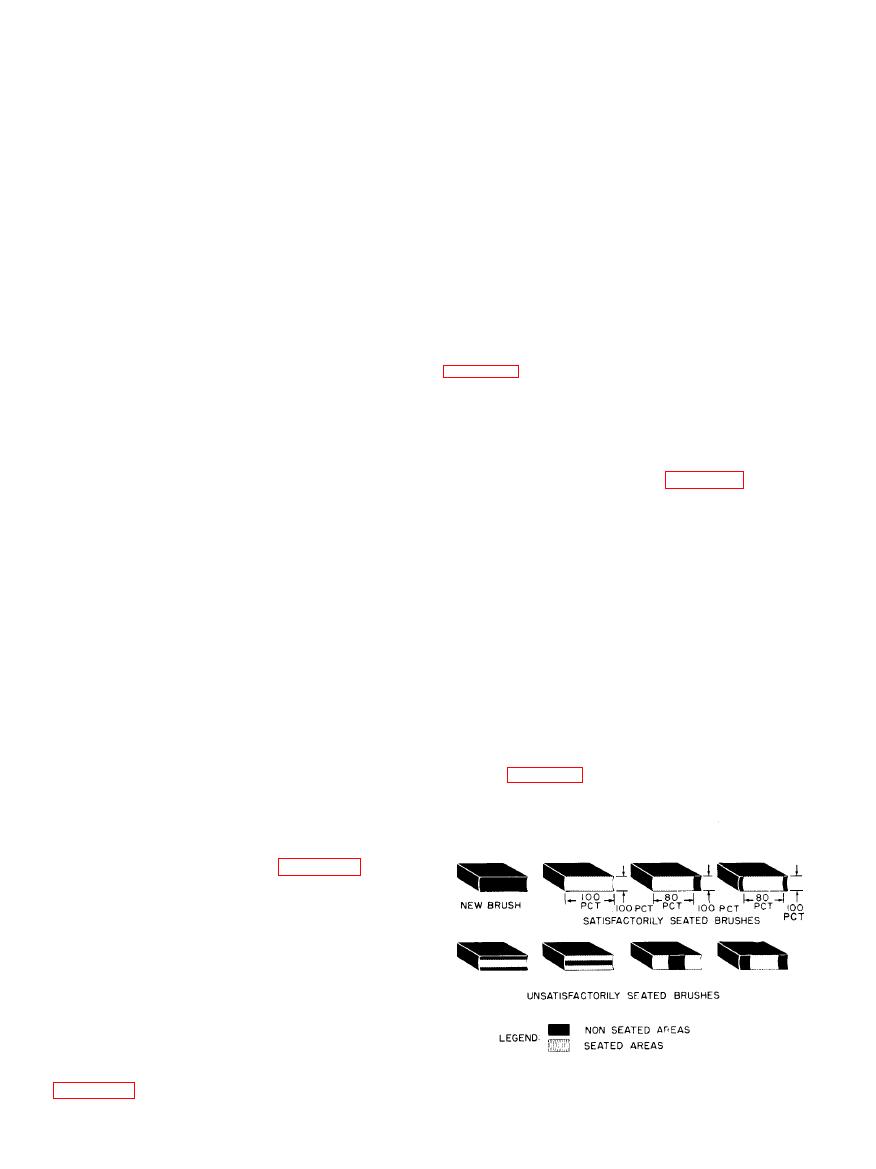

b. Operate the starter generator at the rated

as overheating may occur.

speed until the face of each brush contacts the

commutator 100 percent in the direction of rota-

(4) Mounting. The starter generator should

tion and for at least 75 percent of brush dimen-

be mounted on aircraft generator test stand

sion parallel to the shaft. (See figure 4-1.) There

(7199-1), or an equivalent test stand, capable of

must be no evidence of excessive grooving or

driving the generator continuously over the rated

other surface damage to the face of the brush.

speed. The longitudinal axis of the generator

c. There must be no sparking except for fine

should be horizontal.

pinpoint sparking at the generator brushes.

(5) Excitation. The starter generator should

Brushes should be removed from their brush

be self-excited and controlled by a suitable vari-

holders for periodic inspection.

able resistance with the shunt field.

Note. If the brushes are removed from the

Note. The shunt field current should not be

brush holders, be sure to return each brush to the brush

considered as part of the starter generator load current.

holder from which it was removed.

(6) Load location. The load for the starter

Stall Torque Test

generator should be located so that it will not af-

a. Mount the starter generator on starter

fect the ambient temperature.

torque tester, type B1.

(7) Warm-up. The starter generator should

be operated at a continuous operating speed de-

coupling arm to the spline of drive shaft assem-

livering the rated load at the rated voltage, to

bly (22, figure 31) and place one of the notched

obtain a constant temperature.

ends of the torque coupling arm in the shackle

(8) Voltage measurements. The voltages

suspended from the scale.

should be measured between terminals E and B.

(9) Shunt field voltage. The voltage drop

across the shunt field should be measured be-

tween terminals A and E. (See figure 3-7.)

b. Test Equipment. When performing stall

torque test, use starter torque tester, type B-1.

4-2. Flashing fhe Field

To be sure that the d-c magnetic circuit retains

enough residual magnetism to allow the starter

generator voltage to build up properly, flash the

field as described in steps a through d.

a. Connect the positive terminal of a 12-volt

battery through a singlepole, single throw knife

switch to terminal A+ on terminal board (49,

Figure 4-1. Typical Brush Seating.