TM 5-6115-628-14&P

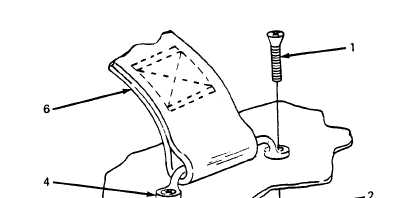

(2) Holding platform (4) in vertical position, position platform on mounting brackets (5) so

holes in platform line up with holes in brackets and install platform anchors (6) in upper

mounting hole on each side of platform.

(3) Secure platform (4) to brackets (5) with two screws (1), four flat washers (2) and two

nuts (3).

4-25.

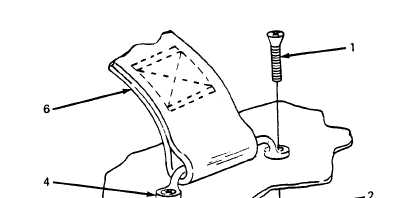

Holddown Strap Replacement. (See figure 4-12). Three holddown straps are provided on the

roadside fender of each power unit. These straps are used to secure the power cables when the power

plant is in transit. Replacement procedure is typical.

a.

b.

4-26.

Removal.

(1) Remove two screws (1, figure 4-12), two washers (2), and two nuts (3) securing foot-

mans loop (4) to trailer (5).

(2) Slide holddown strap (6) off footmans loop (4).

Installation.

(1) Slide holddown strap (6) onto footmans loop (4).

(2) Position footmans loop (4) on

washers (2), and two nuts (3).

trailer body (5) and secure with two screws (1), two

Figure 4-12. Holddown Strap Replacement.

SECTION IX. MAINTENANCE OF ELECTRICAL SYSTEM

General. This section of the manual contains unit level maintenance procedures for electrical

components that are unique to the AN/MJQ-15 power plant. Specifically, this includes the switch box

and the power cables.

4-27.

Cable Testing. A continuity test is used to detect opens or shorts in the power plant power

cables. The following test procedure is typical for both.

a. Set multimeter controls to prepare unit for continuity testing.

4-26