TM 9-6115-730-24

0119

VALVE LASH CHECK - Continued

NOTE

If flywheel is turned beyond point that timing bolt (Figure 3, Item 23) engages in the threaded

hole, the flywheel must be turned opposite normal engine rotation approximately 30 degrees.

Then turn the flywheel in the direction of normal rotation (CCW) until timing bolt (Figure 3,

Item 23) engages with threaded hole. This removes play from gears.

Inlet valves and exhaust valves for the No. 1 cylinder are fully closed if No. 1 piston is on the

compression stroke and the rocker arms can be moved by hand. If the rocker arms cannot be

moved by hand and the valves are slightly open, the No. 1 piston is on the exhaust stroke.

When the actual stroke position is identified and the other stroke is needed, it is necessary to

remove the timing bolt (Figure 3, Item 23) from the flywheel, turn the flywheel counterclockwise

(CCW) 360 degrees, and reinstall the timing bolt (Figure 3, Item 23).

Valve lash is measured between the rocker arm and the valve bridge.

5. Refer to Table 1 for crankshaft positions for valve lash settings. Check inlet valves 1, 2, and 4, and exhaust

valves 1, 3, and 5, against criteria in Table 2.

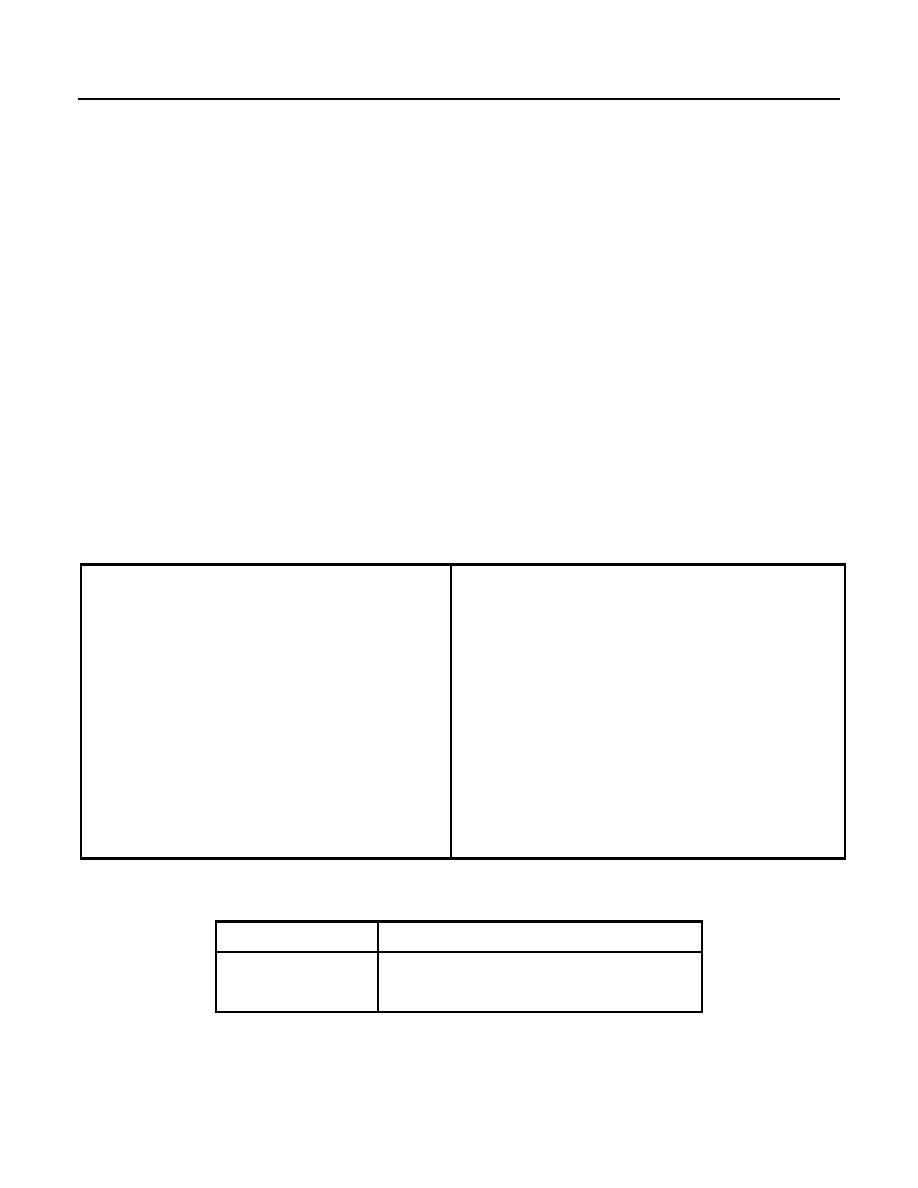

Table 1. Crankshaft Positions for Valve Lash Setting.

Rotation (viewed from flywheel end)

Counterclockwise

Check and adjust with piston no. 1 on this stroke

Top center compression stroke

Inlet Valves

1-2-4

Exhaust Valves

1-3-5

Unit Injectors

3, 5, 6

Check and adjust with no. 6 piston on this stroke

Top center compression stroke

Inlet Valves

3-5-6

Exhaust Valves

2-4-6

Unit Injectors

1, 2, 4

Firing order

1-5-3-6-2-4

Table 2. Check for Valve Lash.

VALVES

ACCEPTABLE RANGE

Inlet

0.012-0.018 in. (0.30-0.46 mm)

Exhaust

0.022-0.028 in. (0.56-0.72 mm)