TM 9-6115-664-13&P

5-14. FLYWHEEL AND RING GEAR MAINTENANCE

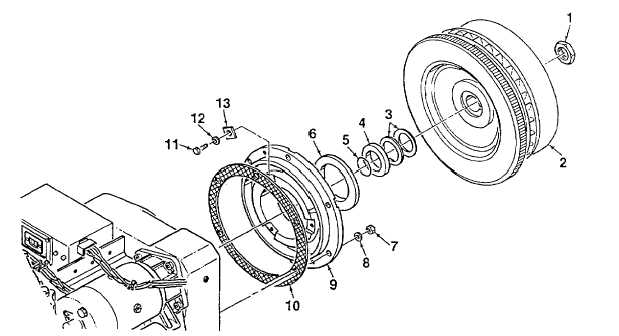

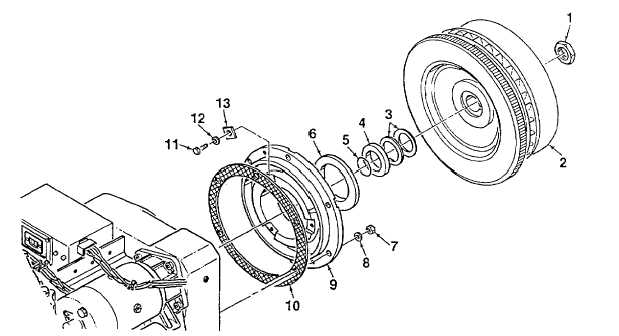

Figure 5-8. Flywheel and Ring Gear

1.

Clean all parts in cleaning solvent and dry thoroughly. Clean engine block mounting surface using a clean rag

dampened with cleaning solvent. Ensure that all cover gasket material is removed from engine block.

2.

Inspect flywheel ring gear teeth for damage. Check for chipped, cracked, or missing teeth. Look for signs of

excessive or unusual wear. Replace flywheel and ring gear as an assembly if damaged.

3.

Inspect flywheel crankshaft bore for damage. Check for scoring. Inspect end of crankshaft for damage. Ensure

crankshaft key is properly seated and free from dirt.

4.

Conduct visual inspection of crankshaft belleville washers, angle ring, and bearing. Check for damage. Look for

scoring or unusual wear.

C.

INSTALLATION.

1.

Mate new cover gasket (10, Figure 5-8) over mounting studs.

2.

Install new oil seal (6), O-ring seal (5), angle ring (4), and belleville washers (3). Install one washer with dish facing

out, and the second washer with the dish facing in.

3.

Install bearing cover (9) over mounting studs and gently hammer into place using a rubber mallet. Install six nuts

(7) and washers (8). Tighten nuts in a criss-cross pattern to ensure even cover installation.

4.

Carefully slide flywheel (2) onto crankshaft, ensuring proper alignment of keyway. Install flywheel nut (1) and torque

to 288 to 303 ft-lbs (390 to 410 Nm).

5-43