TM 9-6115-664-13&P

5-15. CYLINDER, PISTON, AND CRANKSHAFT MAINTENANCE

B.

INSPECTION.

WARNING

Cleaning solvent, PD-680, is potentially dangerous to personnel and property.

Skin and eye protection is required. Good ventilation is required. Avoid repeated

and prolonged skin contact. Do not use near open flame or excessive heat. Flash

point is 200° F (93.3° C).

1.

Clean all parts in cleaning solvent and dry thoroughly.

2.

Visually inspect the crankshaft for scoring on connecting rod journal, bearing journal, and gear journal. Replace

crankshaft if any defects are found.

3.

Inspect the crankshaft bearing journal for grooving, indicated by a ridge around the middle of the journal. Replace

crankshaft if grooving is found. Grooving on the journal indicates that the bearing is also worn and must be

replaced.

4.

Inspect crankshaft gear for broken, cracked, or chipped teeth. Replace gear, if damaged, using a bearing puller.

5.

Inspect bearing for obvious damage. Operate bearing to ensure smooth rotation. Replace bearing if damage is

suspected.

6.

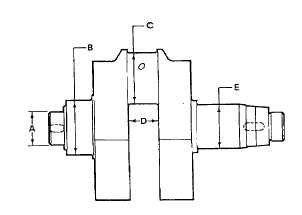

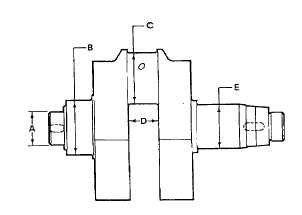

Measure crankshaft dimensions A, B, C, D, and E.

Replace crankshaft if any dimension is beyond

limit.

a.

Dimension A = 35.002 to 35.018 mm (1.3790 to

1.3797 in.)

b.

Dimension B = 55.990 to 56.010 mm (2.2060 to

2.2067 in.)

c.

Dimension C = 51.940 to 51.960 mm (2.0464 to

2.0472 in.)

d.

Dimension D = 30.198 to 30.350 mm (1.1898 to

1.1958 in.)

e.

Dimension E = 45.009 to 45.020 mm (1.7734 to

1.7738 in.)

7.

Measure the ID of crankshaft gear. ID shall be

34.965 to 34.985 mm (1.3776 to 1.3784 in.).

Replace crankshaft if beyond limit.

Figure 5-9. Cylinder, Piston, and Crankshaft

(Sheet 2 of 5)

5-46