ARMY TM 9-6115-644-24

AIR FORCE TO 35C2-3-446-12

MARINE CORPS TM 09249A/09246A-24/2

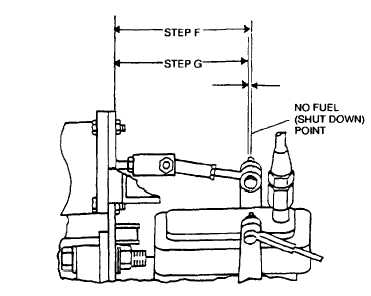

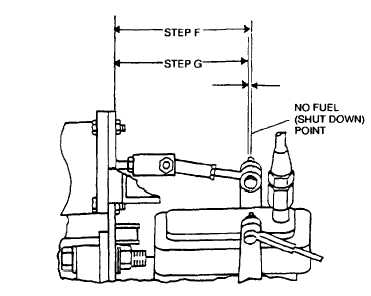

f.

Mark position of fuel injection pump lever on engine block at exact no fuel (shut down) point. Measure injection

pump lever center line position to mounting surface of actuator. Refer to FlGURE 4-9.

g.

Adjust rod assembly (5) and clevis (7) as necessary so that center line of fuel injection pump lever when con-

nected and measured as in step f, will be positioned past the no fuel point by 0.125 to 0.25 inch (3.17 to 6.35

mm). Tighten nuts (6), (19), and (20).

h.

Install rod assembly (5) on fuel injection pump lever with nut (2).

i.

Connect connector (1) to engine harness.

j.

Start generator set, check generator performance and adjust governor control unit as necessary in accordance

with paragraph 4-3-3 .

0.125 - 0.25

FIGURE 4-9. Governor Actuator Adjustment

Section VI. MAINTENANCE OF GENERATOR ASSEMBLY

NOTE

Maintenance procedures for the 50/60 Hz (MEP805A) and 400 Hz (MEP815A) gen-

erators are identical except where noted.

4 - 1 6 TECHNICAL DESCRIPTION.

4-16-1 General. Revolving field type generators have a DC field revolving within a stationary AC winding called the stator.

AC power is distributed from the generator through leads connected to the stator windings. There are no sliding contacts

between the AC winding and the load, therefore, great amounts of power may be drawn from this generator.

NOTE

Refer to FIGURE 4-10 as needed.

4-30