TM 9-6115-624-BD

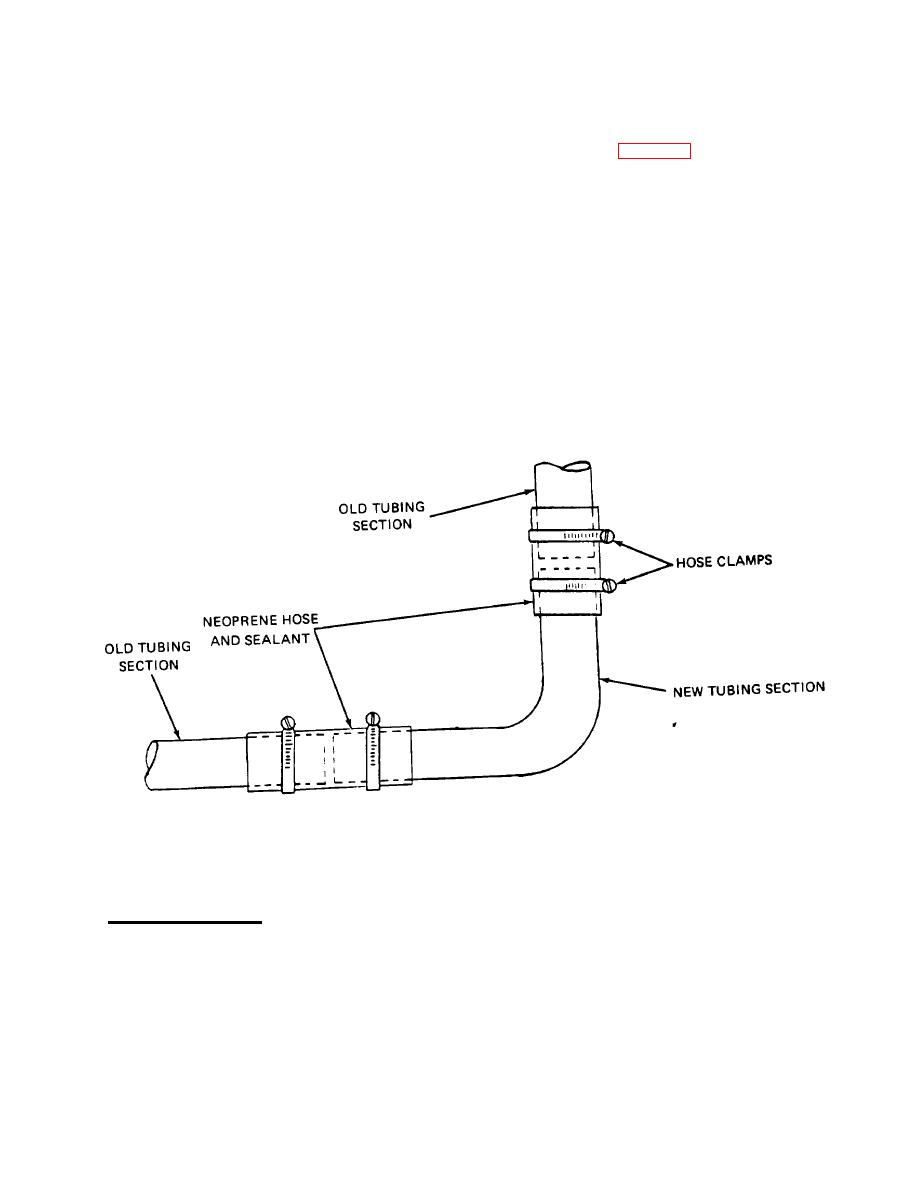

(5) Option 5: Repairing damaged bends.

(a) Cut a bend from an old hydraulic line, mirror arm or similar material (figure 5-8).

(b) Remove the damaged bend from the line.

(c) Clean the cut tubing ends.

(d) Apply sealant to tubing ends.

(e) Using two, 2-inch sections of neoprene hose, install the replacement bend.

(f) Clamp with hose clamps or tightly twisted wire.

(6) Other options: Seal the crack with epoxy.

Record the BDAR action taken. When the mission is completed, as soon as practicable, repair the generator using

standard maintenance procedures.

Figure 5-8. Damaged Bends Repair.

5-16.

Fuel Injector Line, Rupture.

5-17. Option 1: Cut Out Line. If a high pressure fuel line is damaged and there is not time for a better repair, cut the

line and weld or crimp shut the injector pump side. The engine will run for a limited time on fewer cylinders.

5-11