TM 5-6115-631-14&P

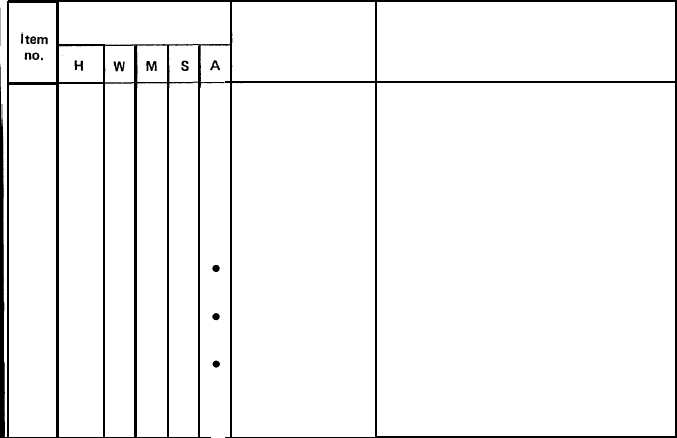

Table 4-1. Unit Preventive Maintenance Checks and Services (PMCS). – CONT.

H – Hours of operation

W – Weekly

M – Monthlv

(As indicated)

S – Semiannually

A – Annually

(40 hours)

(100 hours)

(500 hours)

(1OOO hours)

24

25

26

27

4-13.

Interval

Item to be

Inspected

Brakes – CONT

Wheel Bearings

Hydraulic Brake

Tubes and Hoses

Trailer – Road

Test

Procedures

c.

d.

e.

Inspect hydraulic wheel cylinders for

leaks.

Inspect master cylinder for leaks or low

fluid level. Fill to within 1/2 inch

from top.

Adjust brake (page 4-52,

TM 9-2330-213-14&P).

Clean and repack. (page 4-105,

TM 9-2330-213-14&P).

Inspect for dents, cracks, loose

connections and leaks.

Perform road test paying special attention

to items that were repaired or adjusted.

Section VI. TROUBLESHOOTING

Troubleshooting. Troubleshooting procedures for components unique to the power plant end item

are given in paragraph 4-14. Troubleshooting information for the individual generator sets and trailer

are contained in their respective technical manuals referenced below.

a.

Generator Set Troubleshooting.

Refer to TM 5-6115-584-12 for troubleshooting procedures

applicable to the generator set.

b.

Trailer Troubleshooting.

Refer to TM 9-2330-213-14&P for troubleshooting procedures

applicable to the trailer.

4-14. Power Plant Troubleshooting.

Table 4-2 contains troubleshooting information for locating and

correcting operating troubles which may develop in components unique to the power plant end item. Each

malfunction is followed by a list of tests or inspections which will help determine probable cause and

corrective actions to take. Perform the tests/inspections and corrective actions in the order listed.

This manual cannot list all malfunctions that may occur, nor all tests or inspections and corrective

actions. If a malfunction is not listed or cannot be corrected by listed corrective actions, notify

your supervisor.

4-12 Change 1