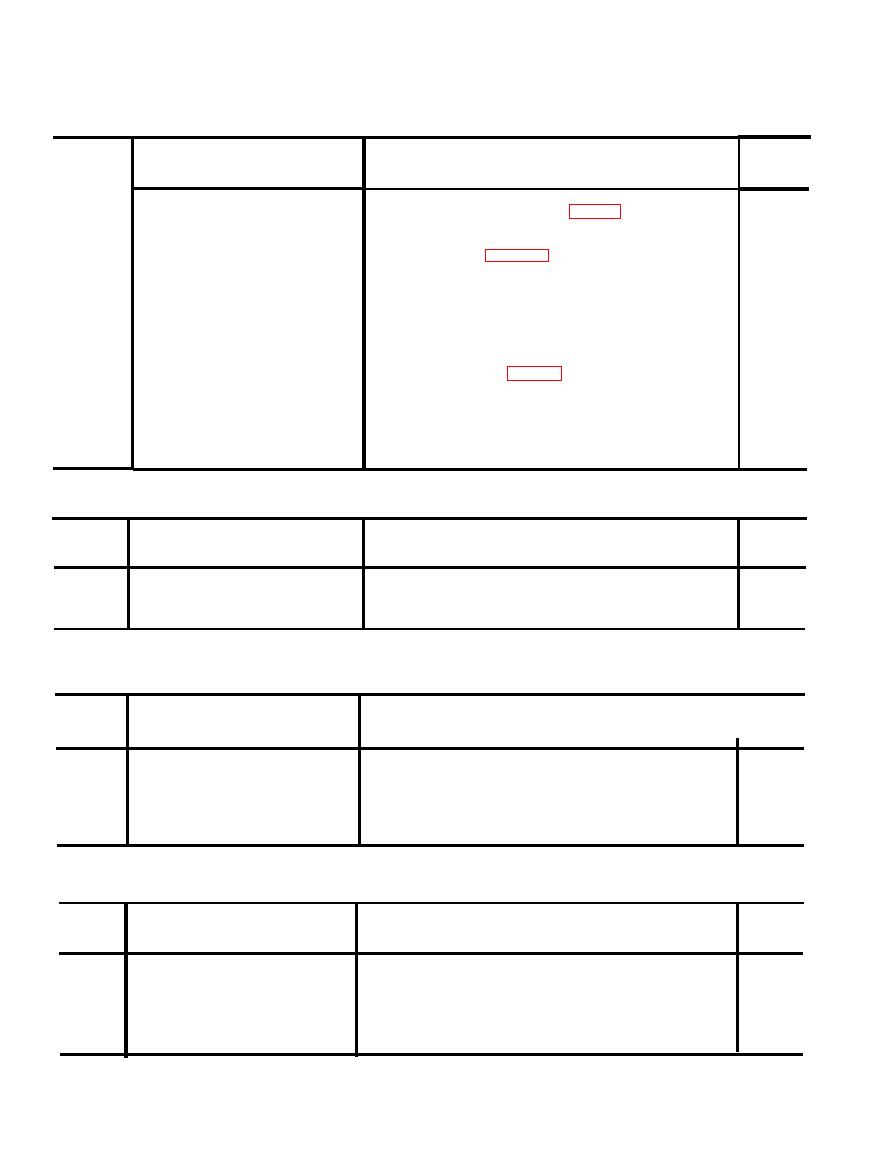

TM 11-6625-680-14-2

Time required: 0.6

WORK

ITEM TO BE INSPECTED

PROCEDURES

TIME

--equence No.

S

--

0.1

1

Completeness . . . . . . . . . . . . . . . . . . See that the equipment is complete (para 1-7)

0.1

2

Exterior surfaces . . . . . . . . . . . . . . . . Clean the exterior surfaces, including the panel and

meter glasses. Check both meter glasses and indicator

lens for cracks (para 3-8)

0.1

3

Connectors. . . . . . . . . . . . Check the tightness of all connectors.

0.1

4

Controls and indicators. . . . . . While making the operating checks (items 5 and 6),

observe that the mechanical action of each switch is

smooth, and free of external or internal binding, and

that there is no excessive looseness. Also, check the

meters for sticking or bent pointers. Replace fuses,

knobs, and lamps as required.

0.1

5

O p e r a t i o n . . . . . . . . . . . . . . . . . . . . . . . . Operate the equipment (para 2-6). The indicator lamp

should glow. The D. C. VOLTS and D. C. AMPS

meters should indicate output voltage and current,

respectively.

0.1

6

D. C. POWER ON switch . . . . . . . . Set to OFF. Note that the 28V. ON indicator lamp

extinguishes.

Time required: 0.2

WORK

Time

Sequence No.

ITEM TO BE INSPECPED

PROCEDURE

(M/H)

0.1

1

Cables . . . . . . . . . . . . . . . . . . . . . . . . . Inspect cables for chafed, cracked, or frayed insulation.

Inspect for loose terminals.

2

0.1

Metal surfaces . . . . . . . . . . . . . . . . . Inspect exposed metal surfaces for rust and corrosion.

Time

required:

0.3

I

WORK

Time

ITEM TO BE INSPECTED

(M/H)

PROCEDURE

Sequence No.

Transformer terminals. . . . . . . . . Inspect the terminals on the power transformer. All

1

0.1

nuts must be tight. There should be no evidence of

dirt or corrosion.

Gaskets and insulators. . . . . . . . . . Inspect gaskets, insulators, bushing and sleeves for

0.1

2

cracks, chipping and excessive wear.

Interior . . . . . . . . . . . . . . . . . . . . . . . .Clean the interior of the chassis and cabinet.

0.1

3

Time required: 0.2

WORK

Time

Sequence No.

ITEM TO BE INSPECTED

(M /H)

PROCEDURE

1

Publications . . . . . . . . . . . . . . . . . . . . See that all publications are complete, serviceable, and

0.1

current (DA Pam 310-4).

2

Modifications . . . . . . . . . . . Check DA pam 310-7 to determine whether new ap-

0.1

plicable MWO's have been published. ALL URGENT

MWO's must be applied immediately. All NORMAL

MWO's must be scheduled.

1