TM 11-6125-252-15

CAUTION

NOTES

When removing the dc brushes, mark the

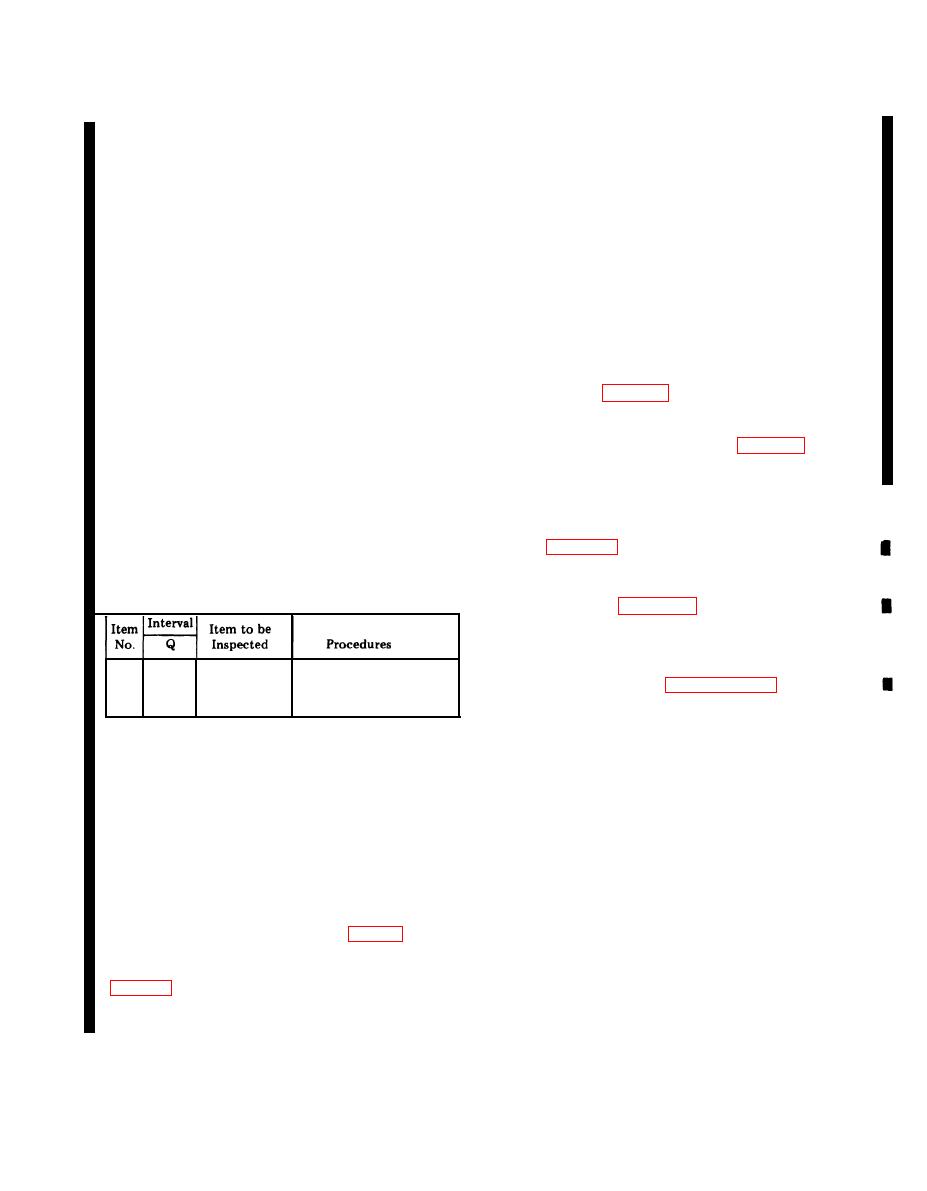

The PROCEDURES column in your PMCS

brushes in a manner which will insure your

charts instruct how to perform the required

replacing them in exactly the same position

checks and services. Carefully follow these

they were in the brush holders before you

instructions and, if tools are needed or the

removed them. Incorrect replacement of

chart so instructs, get higher category main-

dc brushes will cause arcing on commutator

tenance to do the necessary work.

segments a n d thus create noise inter-

If your equipment must be in operation all

ference to equipment and excessive com-

the time, check those items that can be

mutator wear due to the arcing.

checked and serviced without disturbing

b. After initial installation or after new dc

operation. Make the complete checks and

brushes are installed, check the brushes after

services when the equipment can be shut

1000 hours of operation and every 200 hours

down.

Remove the cover plates over the

thereafter.

c. Deficiencies that cannot be corrected must

dc brushes (figs. 4-2 and 5-1). Lift the finger

be reported to higher category maintenance per-

over the brush and lift out the brush. If the

sonnel. Records and reports of preventive main-

working face is worn down to the end of the

tenance must be made in accordance with proce-

wear line, it should be replaced (para 4-8). Replace

dures given in TM 38-750.

the brush exactly as it was removed until a new

NOTE

brush is installed.

The checks in the interval column are to

4-8. Removal and Replacement of Brushes

be performed in the order listed.

Replacement of brushes is required when inspec-

tion (para 4-7) shows that they are worn down

4-4. Organizational Preventive Maintenance

to the wear line. A full set of spare brushes is

Checks and Services Chart

shipped with the motor generator.

Q Quarterly

checking procedure. When replacing with new

brushes, the curvature must be observed to insure

proper seating and contact with the sliprings.

Perform operational check

1

Motor

q

as described in para-

Generator

checking procedure. Remove the machine screws

graph 3-5.

PU-724/G

that secure the brush leads to the brush holders.

Place the new brush in the holder, observing the

curvature and polarity marking. Place the ter-

Paragraph 4-5 deleted.

minal under the machine screw in the holder

Paragraph 4-6 deleted.

and tighten. See that spring and finger move

freely and press down on top of brush in holder.

c. Brushes will reseat to the curvature of the

sliprings and commutator after several hours of

4-7. Checking Brushes

operation.

a. After initial installation or after new brushes

are installed, check the ac brushes after 1000 hours

4 - 9 . Removal and Replacement of Motor

of operation and every 200 hours thereafter. Re-

move the cap of each ac brush (fig. 4-1) and lift

a. Removal.

out the brush. If the working face is worn down to

(1) Remove the dc power cable plug from

the end of the wear line, it should be replaced

its termination point.

moved until a new brush is installed. Do not

(2) Remove any plugs that may have been

interchange brushes.

Change 2

4-3