TM 9-6115-730-24

0083

REPROGRAMMING OR VERIFYING GSC SETPOINTS - Continued

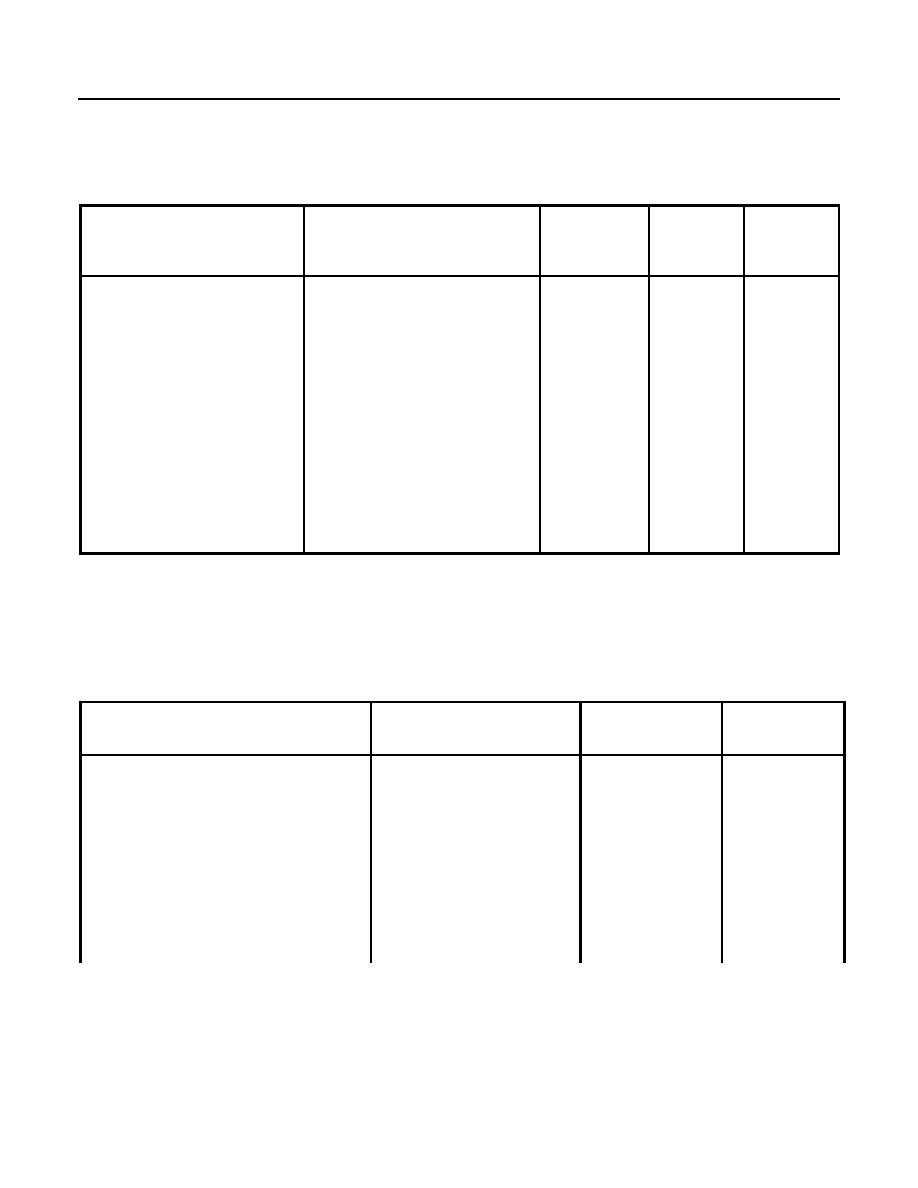

Table 4. 200 kW OP5-0 Engine/Generator Setpoint Programming - Continued.

240/416

120/208

FACTORY

60 Hz

60Hz

(50 Hz) 8

DESCRIPTION

RANGE OF VALUES

DEFAULT

(50 Hz)

P030 Nameplate Power:

0 through 10 MW in increments

400 kW

200 kW

200 kW

Rated power capability of

of 1 kW

(166 kW)

(166 kW)

generator.

P031 Rated Frequency:

50 or 60 Hz

60 Hz

60 Hz

60 Hz

Nominal frequency rating of

(50 Hz)

(50 Hz)

TQG.

P032 Connection

0 Wye

0

0

0

Configuration of Generator:

1 Delta

Wye or Delta configuration of

generator.

P033 Number of Generator

0 through 254 in increments of 2

4

4

4

Poles. 6

1

The setpoints (stored or being programmed) must match the specified setpoints of the TQG.

6

When P033 is programmed to 0 poles, the AL15 (GSC Configuration Error) fault is disabled.

8

Setpoints to be changed from factory defaults to 200 TQG setpoints at switch gear supplier.

Table 5. OP5-1 Protective Relaying Setpoint Programming.

FACTORY

SETPOINTS

60 Hz (50 Hz) 3

DESCRIPTION

RANGE OF VALUES

DEFAULT

P101 Generator Overvoltage Alarm

0 disabled

1

1

Enable: GSC enables or disables

1 enabled

generator overvoltage alarm function.

P102 Generator Overvoltage Alarm

100 to 125% of nameplate

105%

125%

Threshold: Voltage GSC uses to issue

voltage in increments of 1%

overvoltage alarm.

0 through 120 seconds 2 in

P103 Generator Overvoltage Alarm

10 sec

0 sec

Time Delay: Amount of time the FSC+

increments of 1

waits before issuing overvoltage alarm.

____________

2

When programmed to 0 seconds, the actual time is from 0.5 to 1.0 seconds.

3

Setpoints to be changed from factory defaults to 200 TQG setpoints at switch gear supplier.

4

Setpoint values for disabled parameters are for fail safe/pack purposes.