TM 9-6115-730-24

0013

ELECTRONIC TECHNICIAN (ET) TROUBLESHOOTING - Continued

CORRECTIVE ACTION - Continued

STEP 4.

Check the voltage inputs to ENGINE CONTROL switch and to ECM.

a. Set Battery Disconnect Switch to ON. Set DEAD CRANK SWITCH to

NORMAL. On EMCP set ENGINE CONTROL switch to COOL

DOWN/STOP.

b. Check the voltage between engine ground and the test points in Table 1. If

voltage is not present at a test point, the problem is in the device, in the wire

or in the connector that precedes the point in the circuit. Refer to Figure 1

and FO-1, Sheet 2 as required).

(1) If the voltage is 24 3 Vdc at all test points, the wire 800KEY001-P19-T

between ECM connector ENG-P1-70 and connector ENG-P37 is

defective. Repair wire 800KEY001-P19-T and/or connections between

connector ENG-P37 and ECM connector ENG-P1-70 (WP 0088).

(2) If the voltage is not 24 3 Vdc at a test point, repair the device,

FO-2, sheet 2; FO-4, sheets 1-4).

c.

On EMCP set ENGINE CONTROL switch to OFF/RESET. Set Battery

Disconnect Switch to OFF. Set DEAD CRANK SWITCH to OFF.

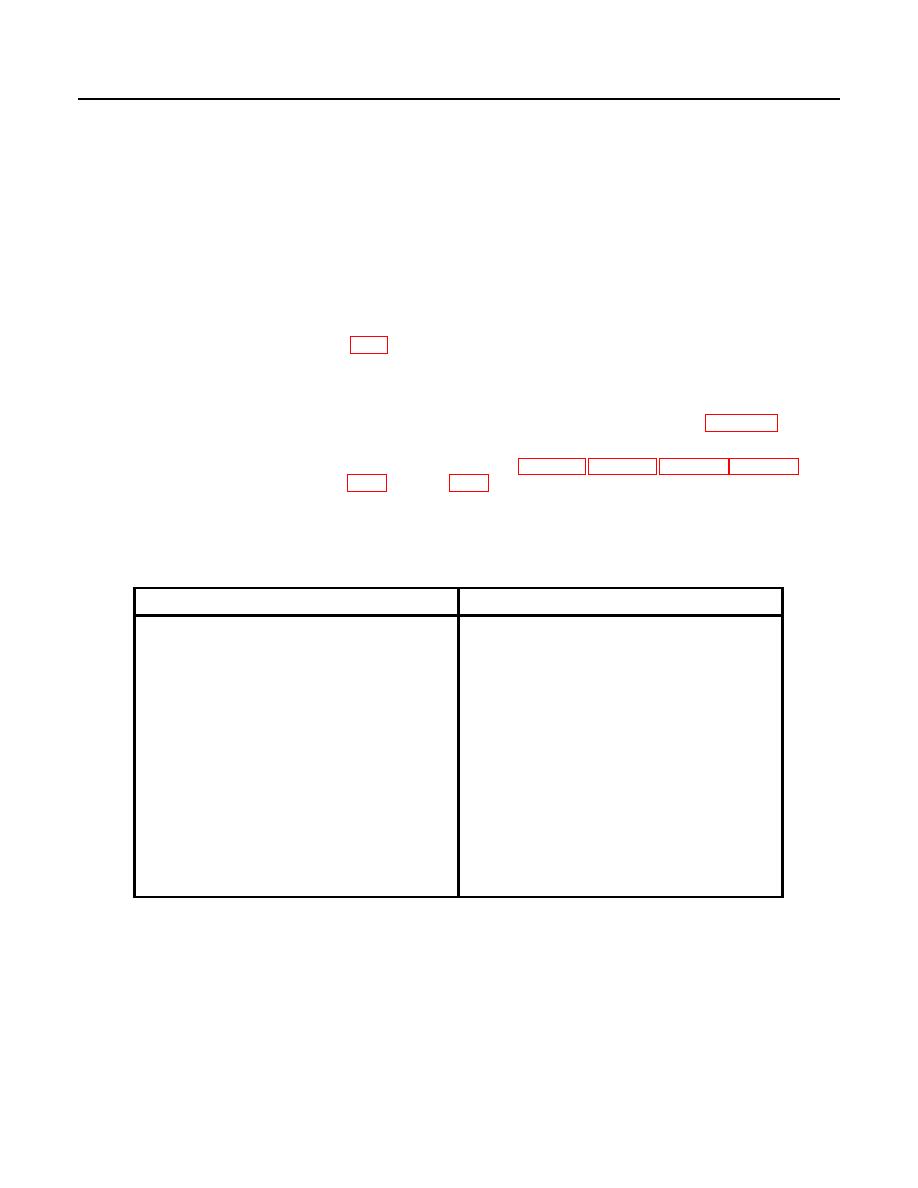

Table 1. ECM Supply Voltage Test Points.

DEVICE (Figure 1)

TERMINAL

Diode D1

Either side

DEAD CRANK SWITCH

Terminals for NORMAL crank

J30/P30 connector

9

Resistor Assembly A7

11

Resistor Assembly A7

12

GSC

RM2

ENGINE CONTROL switch

6

ENGINE CONTROL switch

10

GSC

RM1

GSC

RM39

TB-4

17-22

Connector ENG-P37

40