ARMY TM 9-6115-644-24

AIR FORCE TO 35C2-3-446-12

MARINE CORPS TM 09249A/09246A-24/2

2-64

2-64-1

a.

b.

c.

d.

e.

2-64-2

a.

b.

c.

d.

e.

f.

2-64-3

a.

b.

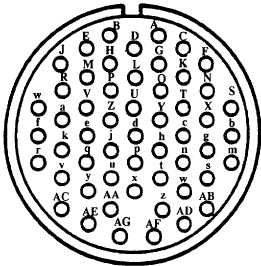

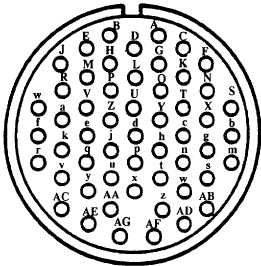

FIGURE 2-17. Diagnostic Connector Pin Positions

PARRALLEL CONNECTOR.

NOTE

Parallel connector is a component of control box harness assembly, but can be re-

moved and installed separately as follows.

Inspection.

Shut down generator set.

Inspect parallel connector for cracks, corrosion, stripped or damaged threads, evidence of shorting or other

damage.

Inspect cap for cracks, corrosion, and broken chain.

Inspect gasket for tears and deterioration.

Replace defective parts.

Removal.

Shut down generator set.

Open battery access door and disconnect negative battery cable.

Remove control box top panel, paragraph 2-15-1.

Tag and disconnect parallel connector (65, FIGURE 2-14) electrical leads by inserting removal tool into pins of

connector.

Remove screws (63), nuts (64), and cap (66).

Remove parallel connector (65) and gasket (67).

Installation.

Install parallel connector (65, FIGURE 2-14), gasket (67), and cap (66) with screws (63) and nuts (64).

Connect electrical leads using insert tool and remove tags.

2-101