TM 5-6115-626-14&P

CHAPTER 5

INTERMEDIATE (FIELD) (DIRECT SUPPORT AND

GENERAL SUPPORT) MAINTENANCE INSTRUCTIONS

Section I. INTRODUCTION

5-1.

General. This chapter contains Intermediate Direct Support and General Support level mainte-

nance procedures for components of the M200A1 trailer added when the trailer is used as part of the

PU-406B/M power unit. These components are not covered in the overall trailer maintenance manual.

For all other intermediate direct and general support maintenance procedures on the trailer, refer to

TM 9-2330-205-14&P. For intermediate direct and general support maintenance procedures on the

generator set, refer to TM 5-6115-465-34.

WARNING

Before performing any maintenance that requires climbing on or under trailer,

set trailer handbrakes, chock wheels, and lower rear leveling jacks. Injury to

personnel could result from trailer suddenly rolling or tipping.

Section Il. MAINTENANCE OF POWER UNIT TRAILER.

5-2. Step and Fender Repair. Repair of the front and rear steps and the fenders is limited to straight-

ening, welding and repainting. If required, repaint in accordance with MIL-T-704, Type F, Color

Green, No. 383 of MIL-C-46168.

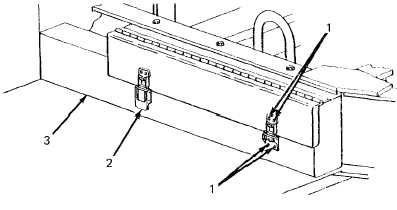

5-3. Accessory Box Repair. (See figure 5-1.) The accessory box is repaired by replacing the latch

and strike assemblies. The box itself may be straightened, welded and repainted. If required, repaint

in accordance with MIL-T-704, Type F, Color Green, No. 383 of MIL-C-46168. Replace latch and

strike assemblies as follows:

a.

b.

c.

Grind off or drill out solid rivets (1, figure 5-1) securing latch and strike assembly (2) to

accessory box (3).

Position new latch and strike assembly (2) on accessory box (3) and secure with solid

rivets (1).

Touch up with paint as required.

Figure 5-1. Accessory Box Repair.

5-1