and the stop pin on the carburetor. The clearance

will cause the lever to bounce back from the stop

pin, rather than jam against the pin, when a load is

suddenly applied to an idling engine. This will

eliminate excessive wear on the threads of the

control rod and ball joints.

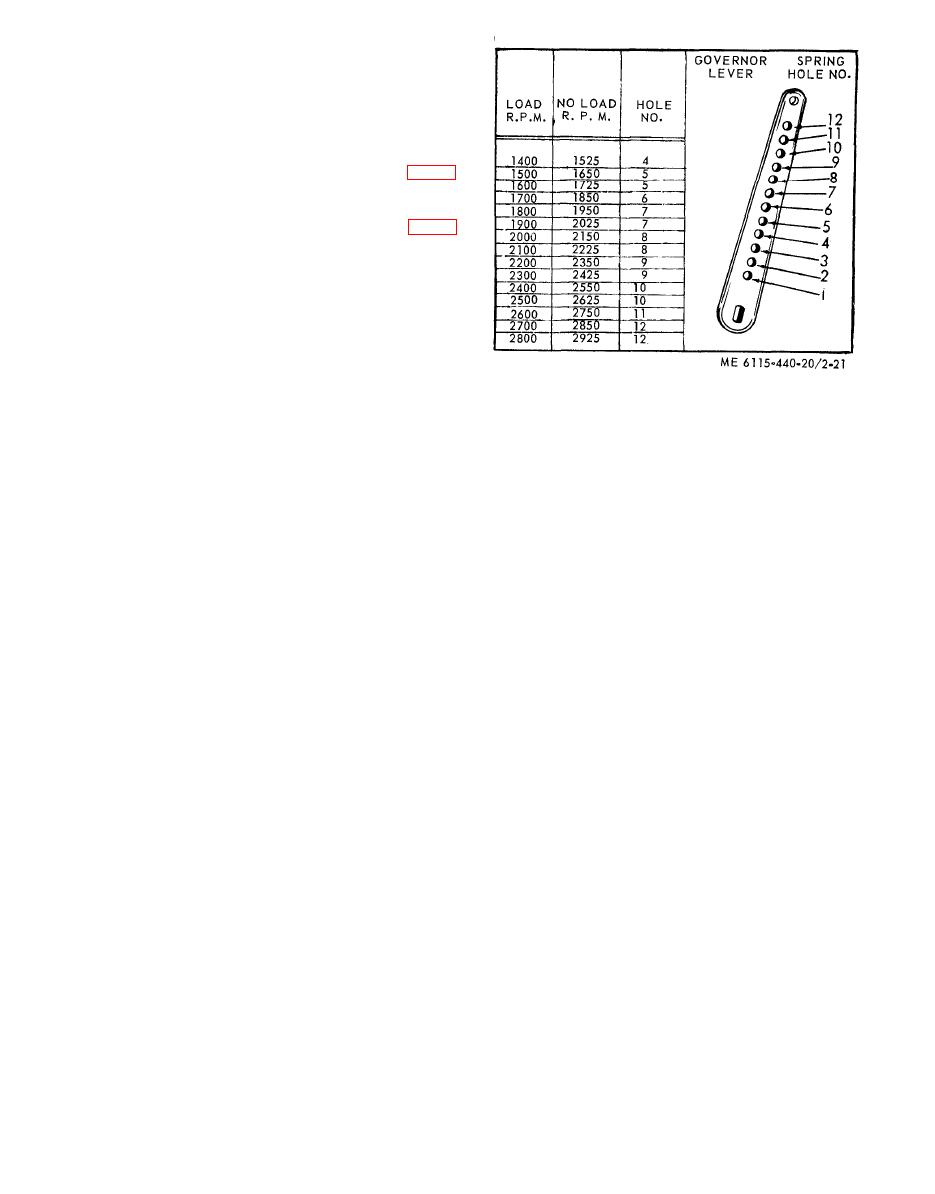

b. The governor lever is furnished with 12 holes

for attaching the governor spring as shown in figure

2-21. It is very important that the spring is hooked

into the proper hole to suit the speed at which the

engine is operated. The governor lever chart (fig. 2-

21) shows the full load and no load speeds of the

engine and the hole corresponding thereto. The full

load speed will be from 150 to 125 revolutions less

than the no load speed. As an example; if the engine

is to be operated at 2000 revolutions per minute

under load, the spring should be hooked into the 8th

hole in the governor lever and the spring tension

adjusted by means of the adjusting screw connected

to the spring, to run 2150 revolutions per minute,

without load. The speed at full load will then be

Figure 2-21. Governor lever adjustment chart.

a p p r o x i m a t e l y 2000 revolutions per minute. A

2-47. Engine Air Shroud and Air Deflector

tachometer or revolution counter should be used

a. General. The engine air shrouds and air

a g a i n s t the crankshaft while making this ad-

deflectors are installed around the cylinder block

justment.