TM 9-6115-730-24

0013

ELECTRONIC TECHNICIAN (ET) TROUBLESHOOTING - Continued

SYMPTOM

8.

Engine Timing Sensor Calibrate.

This procedure is required if a 261-E-13 Engine Timing Calibration code is active. This procedure requires 2

people.

Also use this procedure if any of the following conditions exist:

The ECM has been replaced.

The Engine Timing sensors have been replaced.

The front engine gear group has been serviced.

The following tools (Table 5) are required:

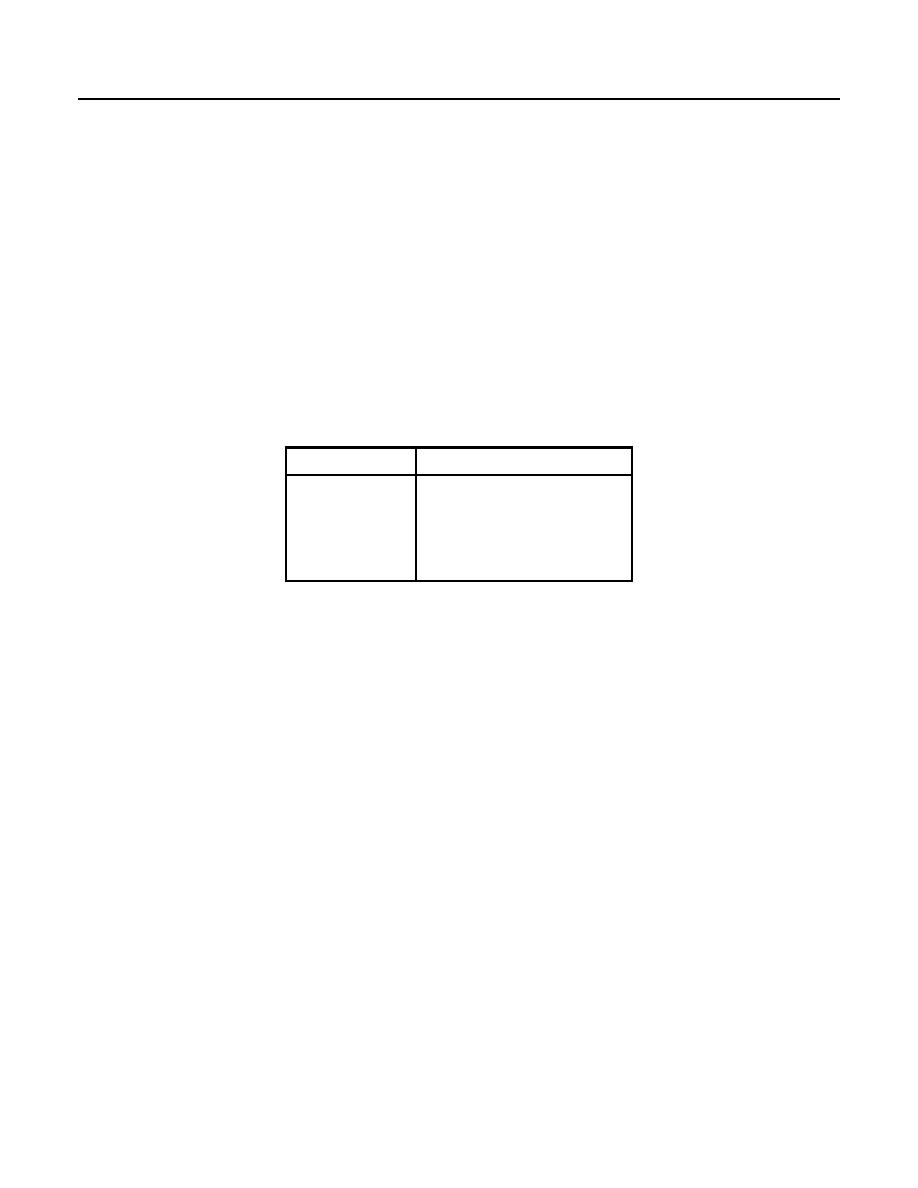

Table 5. Required Tools

PART NUMBER

DESCRIPTION

7X-1171

Transducer Adapter

6V-2197

Transducer

7X-1695

Cable Assembly

170-3519

Harness

MALFUNCTION

Engine timing is not calibrated.

CORRECTIVE ACTION

STEP 1.

On EMCP, set ENGINE CONTROL switch to OFF/RESET. Set Battery

Disconnect Switch to OFF. Set DEAD CRANK SWITCH to OFF.

STEP 2.

Remove timing calibration plug (Figure 7, item 1) from right side of engine.

CAUTION

If crankshaft counterweight is not positioned directly in front of timing calibration port when timing

calibration transducer is installed, damage to the timing calibration transducer will result when

engine is started.

STEP 3.

One person use a flashlight to look for the crankshaft counterweight.

STEP 4

Second person rotates the engine by bumping the DEAD CRANK SWITCH

(quickly setting DEAD CRANK SWITCH to CRANK then back to OFF). Rotate

engine in increments until crankshaft counterweight is positioned directly in front

of the timing calibration port. Adjust crankshaft counterweight position as

required.

STEP 5.

Install the 7X-1171 transducer adapter into the timing calibration port hole.