TM 9-6115-729-24

0085

REPROGRAMMING OR VERIFYING GSC SETPOINTS - Continued

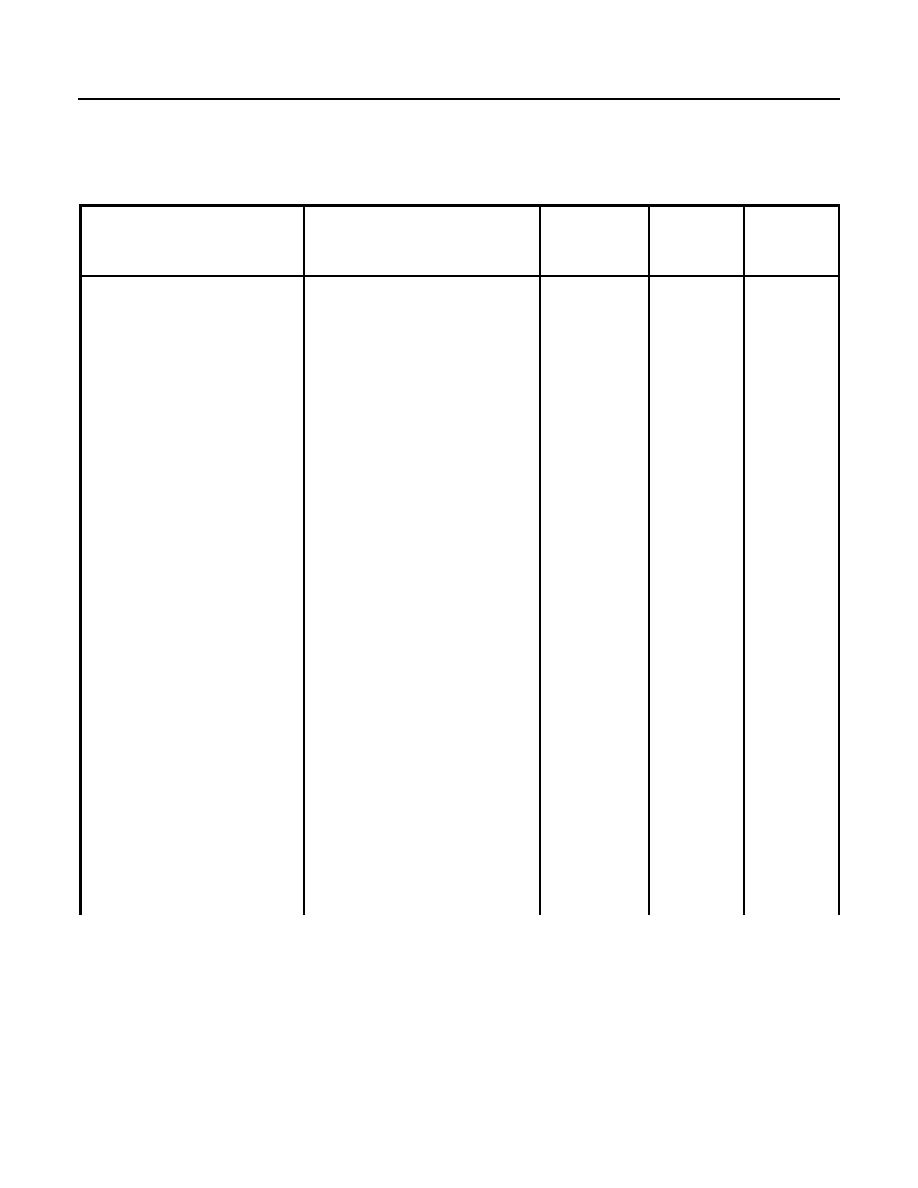

Table 4. 100 kW OP5-0 Engine/Generator Setpoint Programming - Continued.

120/208

240/416

FACTORY

60Hz

60 Hz

(50 Hz) 8

(50 Hz)

DESCRIPTION

RANGE OF VALUES

DEFAULT

P014 Low Oil Pressure

20 to 336 kPa (3 to 49 psi) in

70 kPa

10 psi

10 psi

Shutdown at Idle Speed: Oil

increments of 1

(10 psi)

pressure used by GSC to

declare that a low oil pressure

shutdown fault exists with the

engine at idle speed (the

engine must have been

running for at least 9 seconds

and the engine speed must be

less than oil step speed). 2

P015 High Water

85 to 123C (185 to 253F) in

107C

230F

230F

Temperature Shutdown:

increments of 1

(225F)

Coolant temperature used by

GSC to declare a high coolant

temperature shutdown fault

exists (after a 10 second

delay). 3

P016 Low Water

0 to 36C (32 to 97F) in

21C (70F)

70F

70F

Temperature Alarm: Coolant

increments of 1

temperature used by GSC to

declare that a low coolant

temperature alarm fault exists

(after a 2 second delay).

P017 Total Cycle Crank

5 to 120 seconds in increments

90 sec

90 sec

90 sec

Time: Cycle crank time used

of 1 second

by GSC to declare that an

overcrank fault exists.

P018 Cycle Crank Time:

5 to 60 seconds in increments of

10 sec

30 sec

30 sec

Amount of time GSC cranks

1 second

and then rests the starting

motor during a single crank

cycle.

____________

2

When oil pressure drops to within 34 kPa (5 psi) of the P013 or P014 setpoint, GSC issues a low oil pressure

alarm.

3

When coolant temperature rises to within 6C (11F) of the P015 setpoint, GSC issues high coolant

temperature alarm.

8

Setpoints to be changed from factory defaults to 100 TQG setpoints at switch gear supplier.

0085-15