TM 9-6115-729-24

0013

ELECTRONIC TECHNICIAN (ET) TROUBLESHOOTING - Continued

CORRECTIVE ACTION - Continued

b. Check the voltage between engine ground and the test points in Table 1. If

voltage is not present at a test point, the problem is in the device, in the wire

or in the connector that precedes the point in the circuit. Refer to Figure 3

and FO-1, Sheet 2 as required).

(1) If the voltage is 24 3 Vdc at all test points, the wire 800KEY001-P19-T

between ECM connector ENG-P1-70 and connector ENG-P37 is

defective. Repair wire 800KEY001-P19-T and/or connections between

connector ENG-P37 and ECM connector ENG-P1-70 (WP 0090).

(2) If the voltage is not 24 3 Vdc at a test point, repair the device,

FO-2, sheet 2; FO-4, sheets 1-4).

c.

On EMCP set ENGINE CONTROL switch to OFF/RESET. Set Battery

Disconnect Switch to OFF. Set DEAD CRANK SWITCH to OFF.

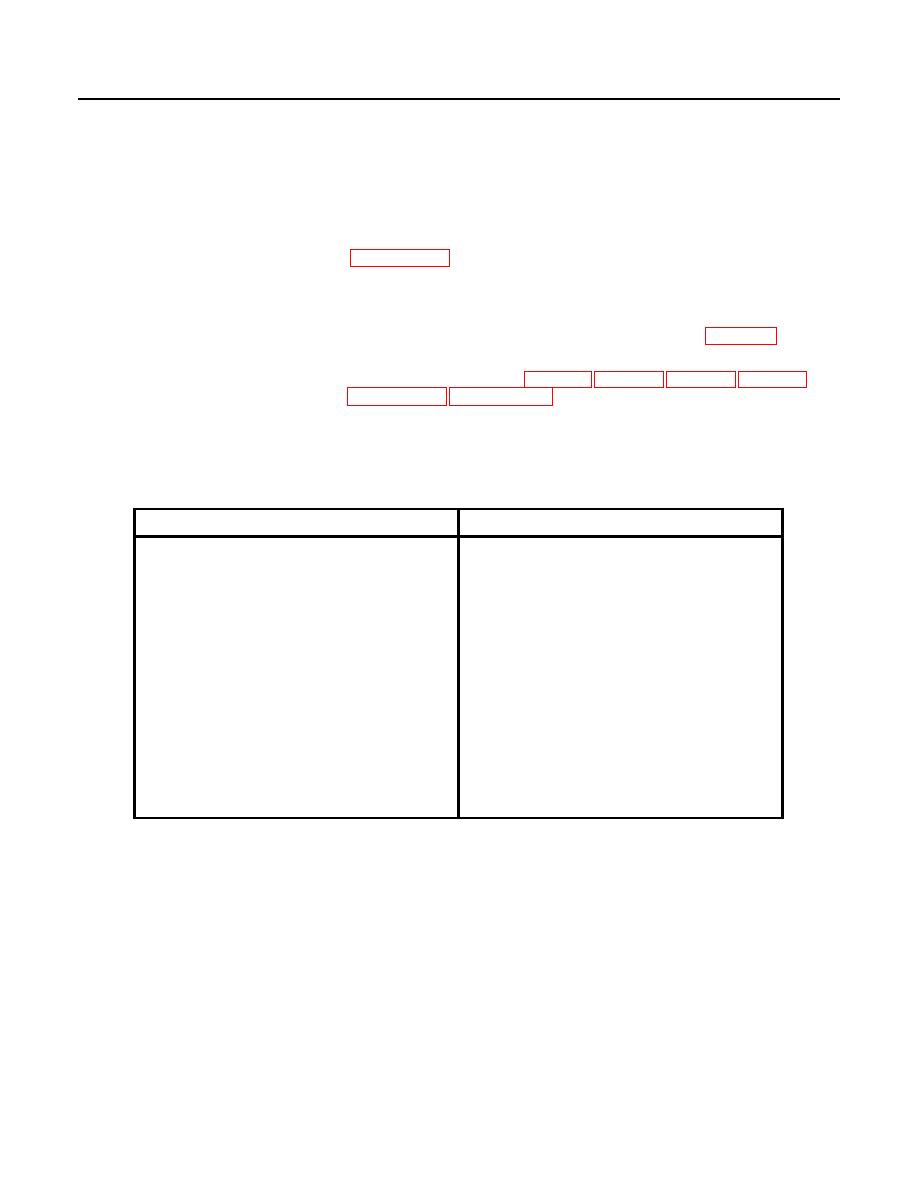

DEVICE (Figure 3)

TERMINAL

Diode D1

Either side

DEAD CRANK SWITCH

Terminals for NORMAL crank

J30/P30 connector

9

Resistor Assembly A7

11

Resistor Assembly A7

12

GSC

RM2

ECS

6

ECS

10

GSC

RM1

GSC

RM39

TB-4

17-22

Connector ENG-P37

40