TM 9-6115-729-10

100 kW TACTICAL QUIET GENERATOR SET

0010 00

TROUBLESHOOTING PROCEDURES Continued

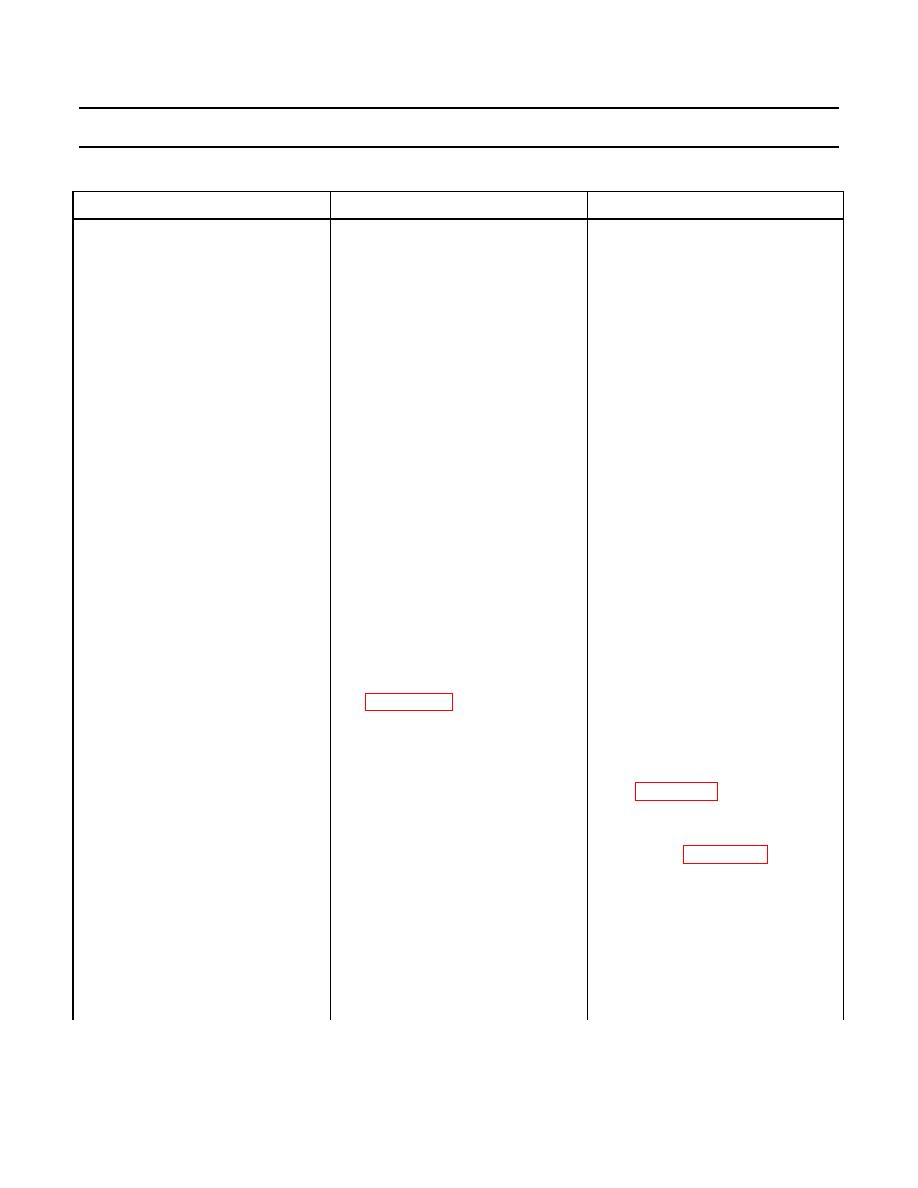

Table 1. Operator Troubleshooting Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

7. Alarm module GENERATOR

3. Set Battery Disconnect Switch to

OVERLOAD amber indicator

OFF.

flashes. TQG disconnects from

load. Continued

4. Check load connected to TQG to

Repair cause of overload or notify

see if there was a problem there that

maintenance.

could cause TQG to overload.

5. Determine if load is too large for

Reduce load below output capacity of

generator set (Power requirement

generator set.

cannot be larger than TQG rating.)

6. Determine if load has been

Reduce load as necessary.

increased.

7. Set Battery Disconnect Switch to

ON.

8. Set DEAD CRANK SWITCH to

NORMAL.

9. Set ENGINE CONTROL switch to

STOP COOL/DOWN.

10. Press LAMP TEST on alarm

module to reset overload fault

detection circuit.

11. Start and operate TQG

1. Monitor TQG for further problems.

(WP 0006 00-11).

2. If there is no identifiable problem

with the load and alarm recurs,

notify maintenance.

8. Alarm module LOW FUEL LEVEL

1. On EMCP, verify low fuel level on

1. If required, service and fill fuel tank

red indicator glows steady. TQG

fuel gauge.

per WP 0016 00.

engine shuts down.

2. Check that auxiliary fuel source is

If needed, connect auxiliary fuel hose

in use.

to TQG per WP 0006 00.

3. On EMCP, verify AUX FUEL

Set AUX FUEL pump switch to ON.

pump switch is set to ON.

4. Verify that external (auxiliary) fuel

If external fuel is present at source,

source is present and that there is

notify maintenance to troubleshoot

fuel in external fuel source

auxiliary fuel pump.

container.

0010 00-7