TM 9-6115-653-14&P

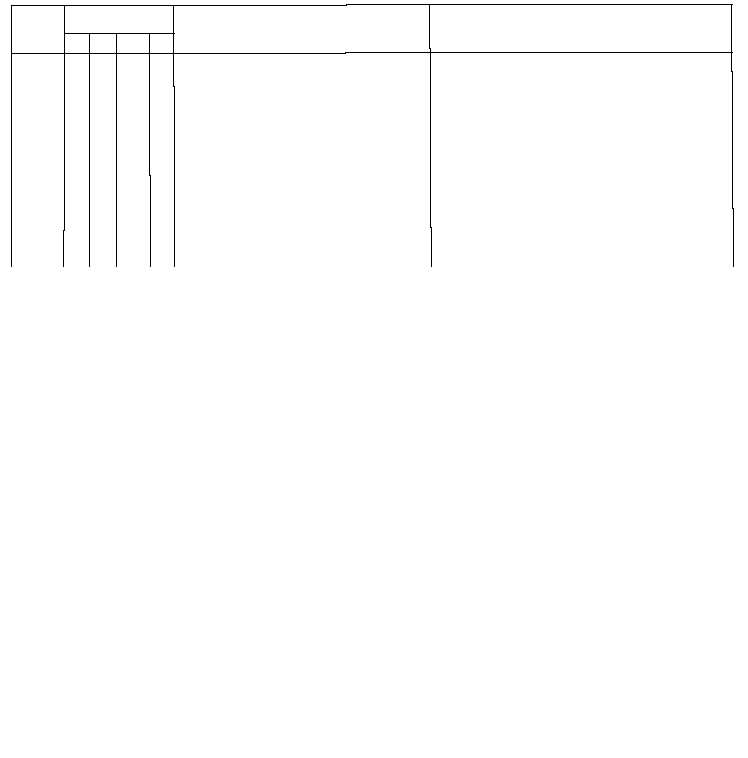

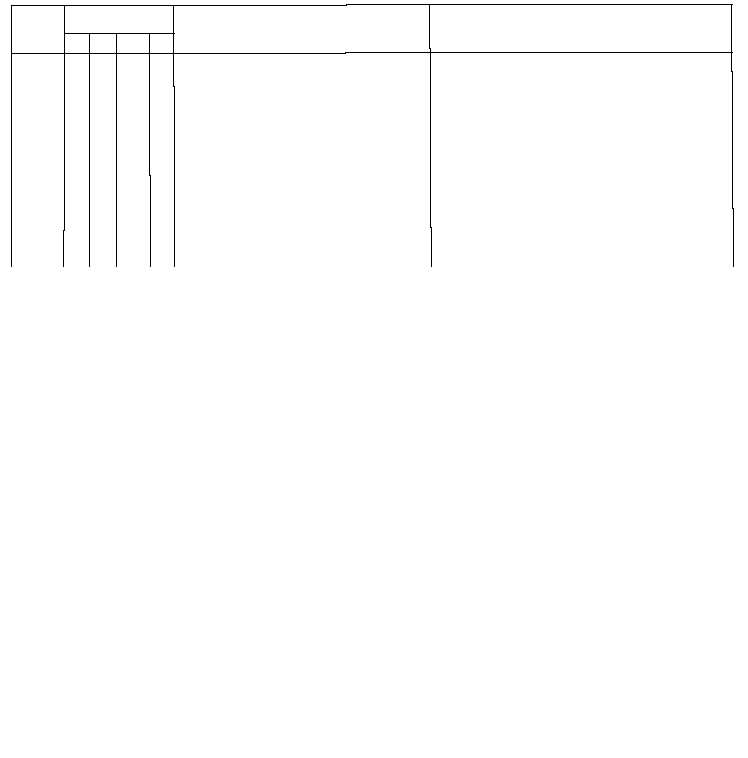

Table 4-1. Unit Preventive Maintenance Checks and Services (PMCS) (cont)

H - Hours of operation

M - Monthly

S - Semiannually

A - Annually

(As indicated

(100 hours)

(500 hours)

1,000 hours)

INTERVAL

ITEM

NO.

H

M

S

A

ITEM TO BE INSPECTED

PROCEDURES

27

Wheel Bearings

Clean and repack wheel bearings

28

Hydraulic Brake Hoses and

Inspect for dents, cracks, loose connections and Fittings leaks

29

Air Hoses and Fittings

Inspect for dents, cracks, loose connections and leaks

30

Brake Master Cylinder

Check fluid level Fill to 1/2 Inch from top

31

Trailer - Road Test

Perform road test paying special attention to items that were

repaired or adjusted, In accordance with TM 9-2330-205-14&P

Section VI. TROUBLESHOOTING

4-13 Power Unit Troubleshooting. There are no troubleshooting procedures authorized at unit level for

the power unit end item . Troubleshooting procedures for the individual generator set and trailer are

contained in their respective technical manuals referenced below:

a.

Generator Set Troubleshooting. Refer to TM 5-6115-464-12 for troubleshooting procedures applicable

to the generator set.

b.

Trailer Troubleshooting. Refer to TM 9-2330-205-14&P for troubleshooting procedures applicable to

the trailer.

Section VII. RADIO INTERFERENCE SUPPRESSION

4-14 General Methods Used to Attain Proper Suppression. Essentially, suppression is attained by

providing a low resistance path to ground for stray currents. The methods used include shielding ignition and

high-frequency wires, grounding the frame with bonding straps, and using filtering systems.

4-15 Radio Interference Suppression Components. All component parts on the power unit end item,

whose primary or secondary function is radio interference suppression, are on the generator set. Refer to

TM 5-6115-464-12 for location of radio interference suppression components

4-12