TM 9-6115-624-BD

7-12. Cable, Heavy Duty, Damaged. Heavy electrical cables are more difficult to repair than small wires; however,

they can be repaired using several different methods. Splicing procedures can be used to repair a break.

a.

Limitations.

None

b.

Personnel/time required.

1 soldier/0.25-1.0 hours

c.

Materials/tools.

Terminal lugs, screw clamp or small hole clamp (item 24, 25, 26, 27, or 28, appx c)

Insulating sleeve or electrical tape (item 22, appx c)

Short bolt with matching nut

Safety wire

Clamp cable (item 3, appx b)

d.

Procedural Steps.

(1) Option 1: Splicing cable with terminal lugs.

(a)

Clean area to be repaired.

(b)

Trim the broken ends of the wire and install an insulating sleeve over one end of the wire.

(c)

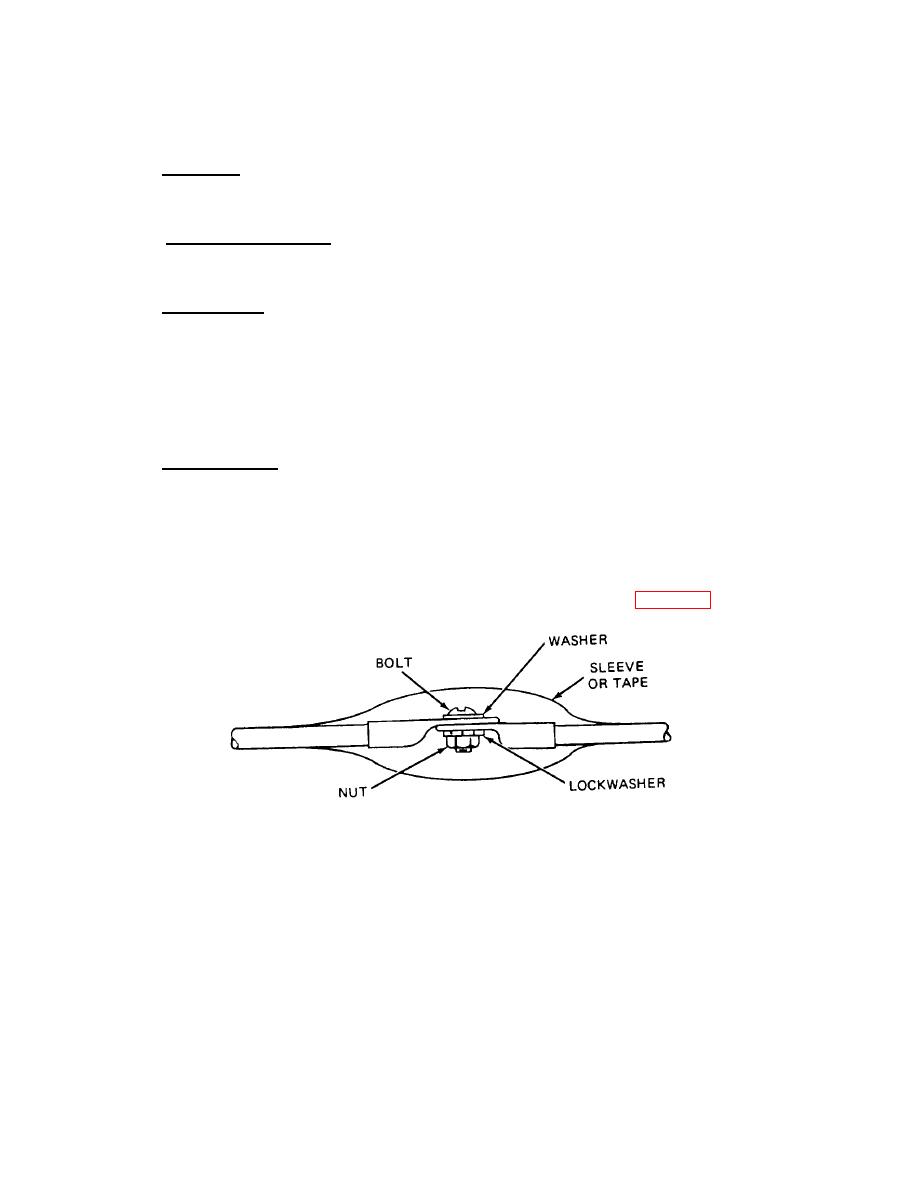

Strip wire and crimp an insulated terminal lug to each wire end (figure 7-8).

Figure 7-8. Splicing Cable with Terminal Lugs.

(d)

Bolt the terminal lugs together using short bolt with nut.

(e)

Slide the insulation sleeve over the connection and either heat-shrink or tie securely at each end.

Tape may be used in place of sleeve.

(2) Option 2: Splicing stranded cable.

(a)

Remove two inches of insulation from each end of broken wire.

7-15