TM 9-6115-729-24

0013

ELECTRONIC TECHNICIAN (ET) TROUBLESHOOTING - Continued

CORRECTIVE ACTION - Continued

WARNING

The high pressure oil system operates at high temperature and pressure. Contact with hot oil can

result in burns and scalding. Shut down generator set, and allow system to cool before performing

checks, services, and maintenance. Wear heat resistant gloves and avoid contacting hot surfaces. Do

not allow hot oil or components to contact skin or hands. Failure to comply can cause injury or death

to personnel.

STEP 7.

Compare the sensor's output to a pressure gauge.

a. On EMCP set ENGINE CONTROL switch to OFF/RESET. Set Battery

Disconnect Switch to OFF. Set DEAD CRANK SWITCH to OFF.

b. Install an 8T-0852 pressure gauge or equivalent in one of the unused oil

ports in the high pressure oil rail on the left side of the cylinder head.

c.

Set Battery Disconnect Switch to ON. Set DEAD CRANK SWITCH to

NORMAL. On EMCP set ENGINE CONTROL switch to COOL

DOWN/STOP.

d. On EMCP set ENGINE CONTROL switch to MANUAL START. The engine

should start.

e. Go to the Injection Actuation Pressure Test on the diagnostic menu of the

Cat ET.

f.

Start the Injection Actuation Pressure Test.

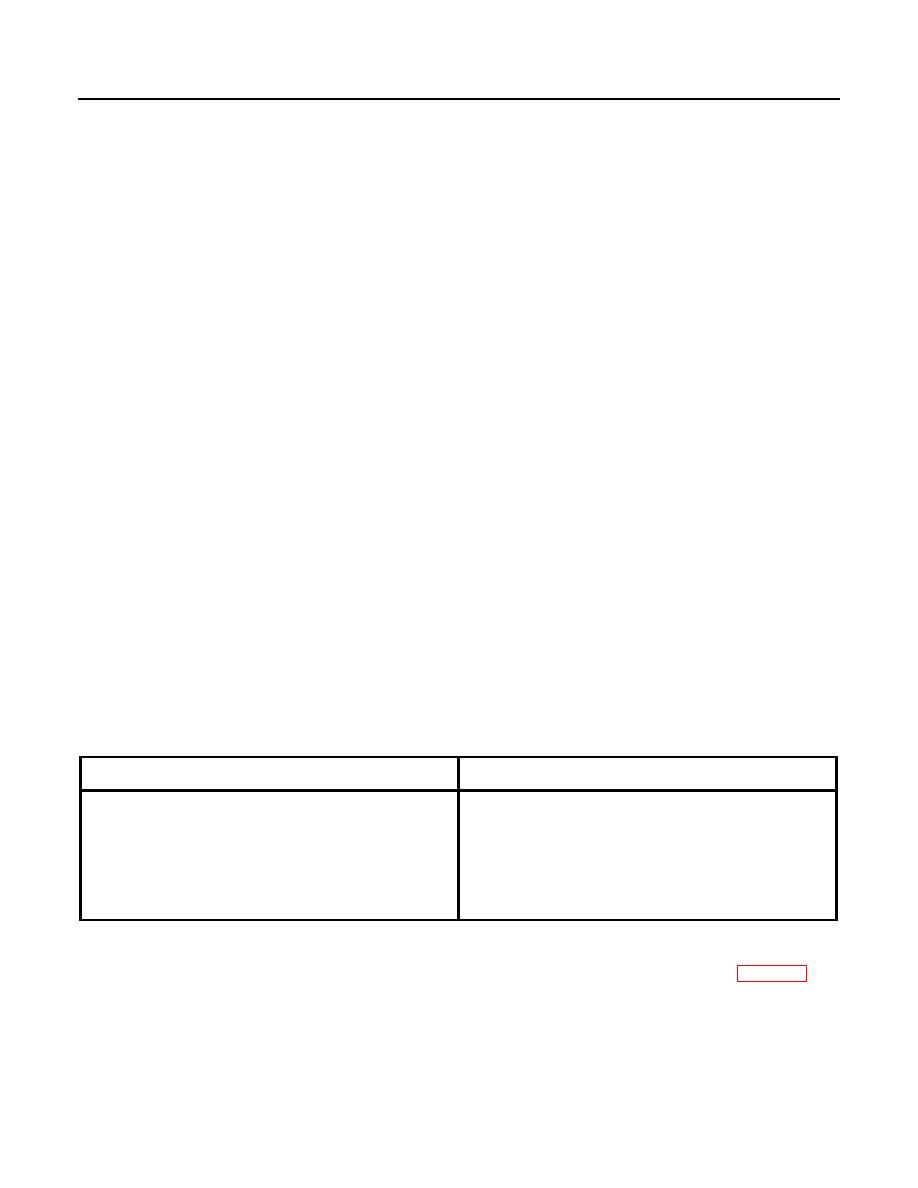

g. Refer to Table 6. Observe the value of the injection actuation pressure on the

Cat ET. Vary the engine speed in order to obtain each injection actuation

pressure value that is listed in the Table. For each pressure value, observe

the reading on the pressure gauge.

PRESSURE READING FROM ET TOOL

RANGE OF READINGS FROM PRESSURE GAUGE

6000 kPa (870 psi)

4000 to 7800 kPa (580 to 1130 psi)

10000 kPa (1450 psi)

8000 to 11800 kPa (1160 to 1710 psi)

15000 kPa (2175 psi)

13000 to 16800 kPa (1885 to 2435 psi)

23000 kPa (3336 psi)

21000 to 24800 kPa (3045 to 3595 psi)

h. If at least one of the values on the pressure gauge is not within the

specification, install a new injection actuation pressure sensor (WP 0100)

and repeat the test. If the new sensor corrects the problem, leave the new

sensor in place. If the new sensor does not correct the problem, the

pressure gauge is faulty. Obtain a new pressure gauge and repeat the test.