ARMY TM 9-6115-671-14

AIR FORCE TO 35C2-3-446-32

MARINE CORPS TM 09249A/09246A-14

5-51

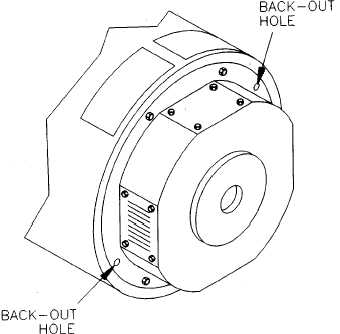

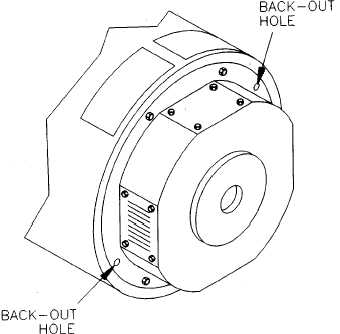

FIGURE 5-10. END BELL REMOVAL

b. Installation.

CAUTION

If bearing needs to be removed for any reason, always install new bearing.

Main bearing is easily damaged when removed from rotor shaft. Failure to

install a new bearing can cause damage to equipment.

(1)

Heat new bearing (9, Figure 5-9) to expand diameter to fit on main rotor shaft (10). Install new

bearing (9) on main rotor shaft (10). Ensure bearing is seated squarely against shaft shoulder by

applying pressure to inner race only.

(2)

Position bearing (9) in end bell (7).

NOTE

It may be necessary to use a lifting device to raise and align end ball with

generator housing.

(3)

Position end bell (7), with exciter stator (16) attached, on generator housing (11) while pulling

slack of wires F1 and F2 through side of generator housing. Secure end bell with lockwashers

(6) and bolts (5). Torque bolts to 59-61 in-lb (6.7-7.0 Nm).

(4)

Tighten lead clamp assembly (33) at side of generator housing (11), ensuring generator leads are

clamped securely.