ARMY TM 9-6115-670-14&P

1-18

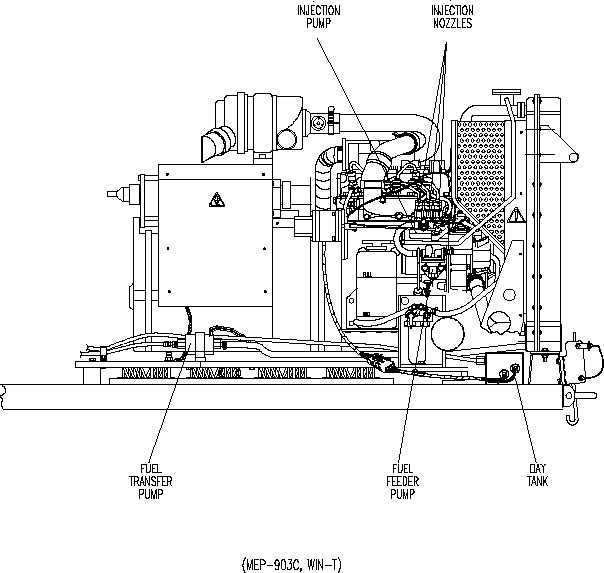

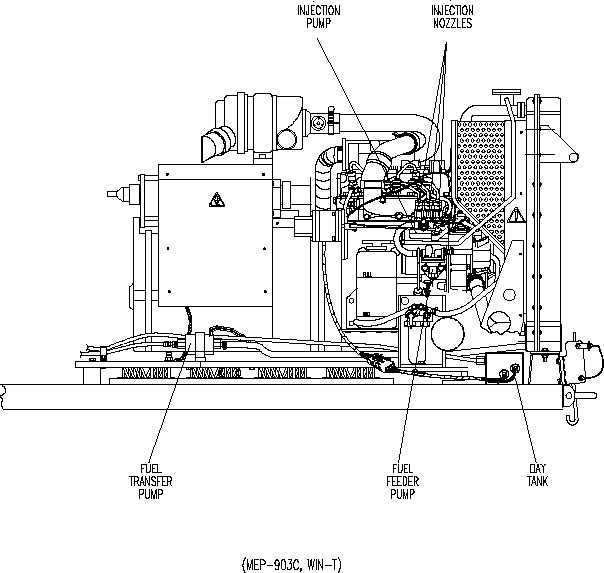

1.16.4. Fuel System. The fuel system (Figure 1-6) consists of a fuel transfer pump, small fuel reservoir

(day tank), a fuel filter, a fuel feeder pump, and injection pump, and three injection nozzles. The fuel

transfer pump draws fuel from the fuel tank of the host vehicle and feeds it to the day tank. The day tank

is used to keep a small amount of fuel in the system so that it never runs dry, which would require

priming the system each time it was started. The fuel filter receives the vehicle fuel from the day tank,

and removes impurities such as dirt and water. The fuel feeder pump draws fuel from the filter and feeds

it to the injection pump. The injection pump pressurizes the fuel to the opening pressure of the injection

nozzles (between 1991 to 2062psi (13.72 to 14.22 KPa) from which it is injected into the combustion

chamber. The injection pump and the injection nozzles use the engine fuel as a lubricant. Therefore, it is

extremely important for the filter to remove dirt from the fuel and water accumulated in the tank. The

injection nozzles are throttle type. Fuel pressurized by the injection pump pushes the nozzle's needle

valve up allowing the fuel to enter the combustion chamber. Excessive fuel flow passes from the nozzle

holder through a banjo fitting and returns to the fuel tank through a fuel overflow pipe. A governor

controls the amount of fuel fed into the engine throughout the entire speed range, preventing the engine

from changing its speed with variations in the load.

Figure 1-6. Fuel System