TM 9-6115-664-13&P

Table 2-1. Operator Preventive Maintenance Checks and Services for APU MEP-952B

Item

Interval

Location:

Procedure

Not Fully Mission

No.

Item to

Capable If:

Check/

Service

1

Before

Overall

a.

Inspect for cracks, leaks, dents,

Class II oil or any fuel

Generator

corrosion.

leaks are present.

Set

Significant cracks exist

b.

Inspect for loose hardware.

in enclosure or components.

2

Before

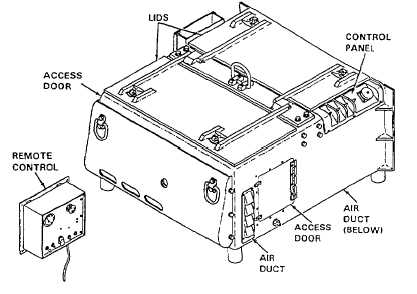

Enclosure

a.

Inspect top lifting lids for security of

Lids are not secure.

attachment. Check that lid latches are

Latches do not lock,

secure and lock properly.

allowing lids or doors to

flap open. Ducts are

b.

Inspect engine access doors for security

obstructed or blocked.

of attachment. Check that door latches

are secure and lock properly.

c.

Inspect air intake and exhaust ducts for

obstructions and blockages. Clear

obstructions and check ducts for

damage.

3

Before

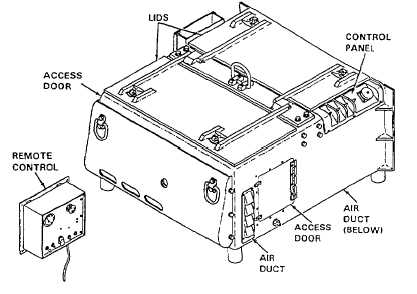

Local

a.

Inspect for security of attachment.

Control or indicator is

Control

Check for obvious damage to switches

damaged to the point it

Panel

and controls.

will effect safe operation.

(or Remote

LED or test point

Control

b.

Open rear lid. Inspect LED indicators

is damaged.

Panel, as

and test points on local control panel

required)

for damage.

2-11