ARMY TM 9-6115-641-24

AIR FORCE TO 35C2-3-456-12

4-11-1. Removal/Disassembly. - Continued.

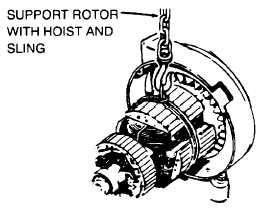

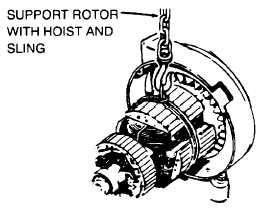

Figure 4-23. Support of Rotor Assembly

NOTE

Use securing device to keep flywheel/generator fan (20) from turning.

1.

Remove bolts (1 7), washers (1 8), Iockwashers (19), and rotor assembly (16) from engine flywheel/generator

fan (20).

m. Remove bolts (22), washers (23), Iockwashers (23), and drive disc (25) from rotor assembly (16).

n. Using gear puller, remove bearing (26) from rotor assembly (16).

o. Tag and disconnect F1 + and F2- leads (29) from rotating rectifiers by removing nuts (27) and washers (28).

p. Using gear puller, carefully remove exciter rotor (30) from rotor assembly (16).

q.

Remove thru-bolts (31) from engine/generator adapter (15).

r.

Remove bolts (32) and engine flywheel/generator fan (20) from engine crankshaft.

4-11-2. Inspection.

a.

Inspect end bell assembly (5, Figure 4–24) for cracks, torn packing (11), broken terminal board (13), and other

damage.

b. Inspect exciter stator (10) for broken windings, evidence of overheating, damaged insulation, and loose termi-

nal ends.

c.

Inspect bearing (26) for looseness and evidence of overheating.

d. Inspect exciter rotor (30) for broken windings, evidence of overheating, damaged insulation, and other damage.

e.

Inspect rotor assembly (16) for broken windings, evidence of overheating, damaged insulation, and loose termi-

nal ends.

f.

Inspect stator(14) for broken windings, evidence of overheating, damaged insulation, loose terminal ends, and

damaged housing.

g.

Inspect drive disc (25) for bends, cracks, elongated mounting holes, and other damage.

h. Inspect flywheel/generator fan (20) for cracks, bent or broken fan blades, broken teeth, stripped threads, and

other damage.

4-27