TM 9-6115-624-BD

(c)

Remove rod and weld.

(d)

Remove all metal fragments which would hinder rod operation.

(2)

Option 2: Welding equipment is not available.

(a)

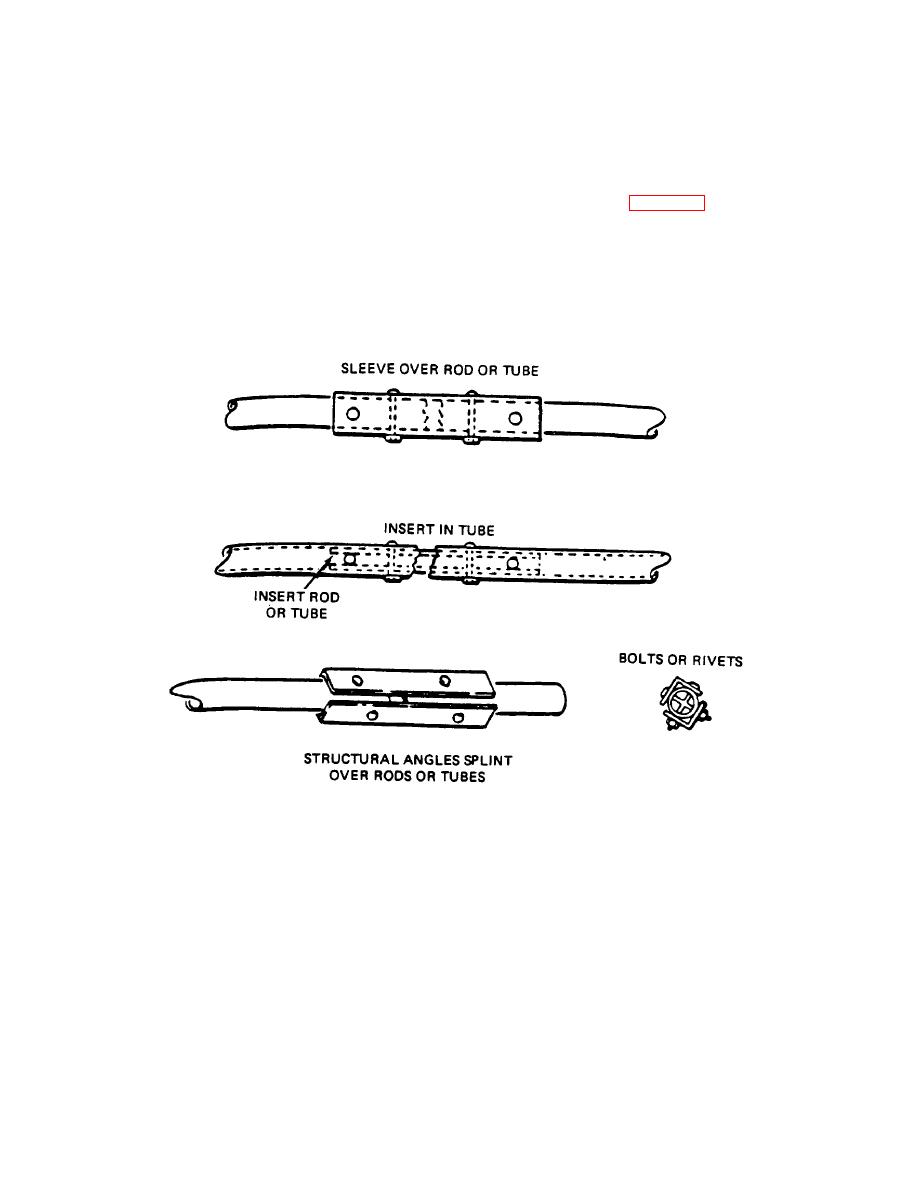

Cut needed material from bussie rack or hand rails to splint rod (figure 3-4).

(b)

Measure rod length and drill holes through reinforcement and rod.

(c)

Rivet or bolt reinforcement to damaged rod.

(3)

Other options: When push/pull damage is beyond repair, a substitute may be manufactured from plate

stock.

Figure 3-4. Push/Pull Rod Damage Repair with Splint.

Record the BDAR action taken. When the mission is completed, as soon as practicable, repair the generator using

standard maintenance procedures.

3-19. Pin Alignment, Clevis, Cotter, Dowels, Quick Release, Etc. Most linkage have retainer devices, cotter keys,

lacing wire or safety pins, to keep the connecting bolts or pins in place. During BDAR repairs, small pins may become

lost or forgotten which will cause linkage or component failure. Repairing the generator by securing connecting bolts, or

pins can be accomplished using wire, welding rod, bolts or nails. Place the item through the hole and bend the ends to

keep it from falling out. Castelated nuts can also be retained using this method. Alignment pins or dowels can be

replaced with cut bolts. Use a bolt that is a tight fit in the hole, tap the bolt in and cut to proper length.

3-10