TM 5-6115-631-14&P

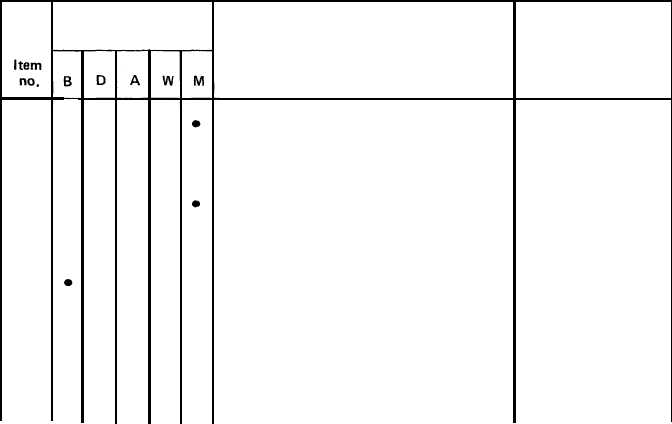

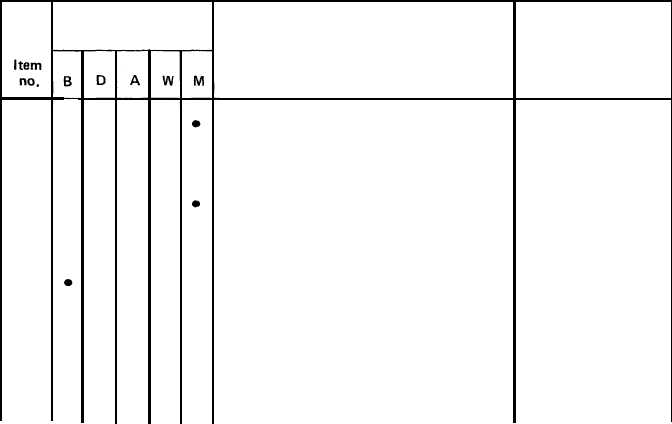

Table 3.2. Operator/Crew Preventive Maintenance Checks and Services (PMCS) – CONT.

B - Before

D – During

A – After

W - Weekly

28

29

30

Interval

Item to be inspected.

Procedure: check for and

have repaired, filled, or

adjusted as needed.

FIRE EXTINGUISHER

Inspect and weigh fire extinguisher.

(See paragraph 3-12.)

TRAILER FRAME

Inspect entire chassis frame for damage,

cracks, and broken welds.

SWITCH BOX

Inspect for broken or damaged connectors

Inspect for frayed or broken wires and wire

insulation. Inspect for loose connections

at the switch box. Inspect rotary

switch for loose or missing parts and

correct operation.

M – Monthly

Equipment is not

ready/available if:

Frame is obviouslv

broken or cracked.

Connectors will not

tighten or if parts

are damaged or

missing, bare wires

are exposed or if

rotary switch is

defective or

unoperational.

Section IV TROUBLESHOOTING

3-10. Power Unit Troubleshooting. There are no troubleshooting procedures authorized at operator level

for the power plant end item. Troubleshooting procedures for the individual generator sets and trailer

are contained in their respective technical manuals referenced below.

a.

Generator Set Troubleshooting. Refer to TM 5-6115-584-12 for troubleshooting procedures.

b.

Trailer Troubleshooting. Refer to TM 9-2330-213-14&P for troubleshooting procedures.

Section V. OPERATOR/CREW MAINTENANCE

3-11. Enclosure Maintenance.

Maintenance of the enclosure at operator level is limited to replacement

of the fitted cover and/or the bows.

a.

Fitted Cover Replacement. (See figures 3-1 and 3-2.)

(1) Removal.

(a) Untie 25 ropes ( 1, figure 3-1 )

fastening fitted cover to trailer body (2).

Change 1

3-19