TM11-6125-256-34

ASSEMBLY 4B93-1-A

ing voltage measurements as described in paragraph

4-10.1. Inspection

4-10 3

a Inspect printed wiring board (43, fig 4-5 1) for

signs of damage

b Inspect wiring for loose or broken connections

Fig 4-3 1 shows the wiring connections for the volt-

age and frequency regulator assembly

c Check variable resistors R5 and R23 (13 and 1,

fig 4-5 1) and heat-sink mounted transistors Q6 and

Q11 (17) for signs of overheating or other damage

and Frequency Regulator Assembly

a Install the voltage and frequency regulator assem-

bly in a known good motor-generator PU-750A/A as

described in paragraph 3-14b

b Connect the motor-generator for testing as de-

scribed in table 3-4, using an input voltage of 28 volts

dc and no load on the generator If the motor speed is

voltage frequency regulator assembly 4B93-1-A

in excess of the 400-Hz speed to a point where the

motor attempts to run away, turn off power and per-

(3) Rotate the frequency adjustment potentiom-

form the following procedure

eter fully counterclockwise and then fully clockwise

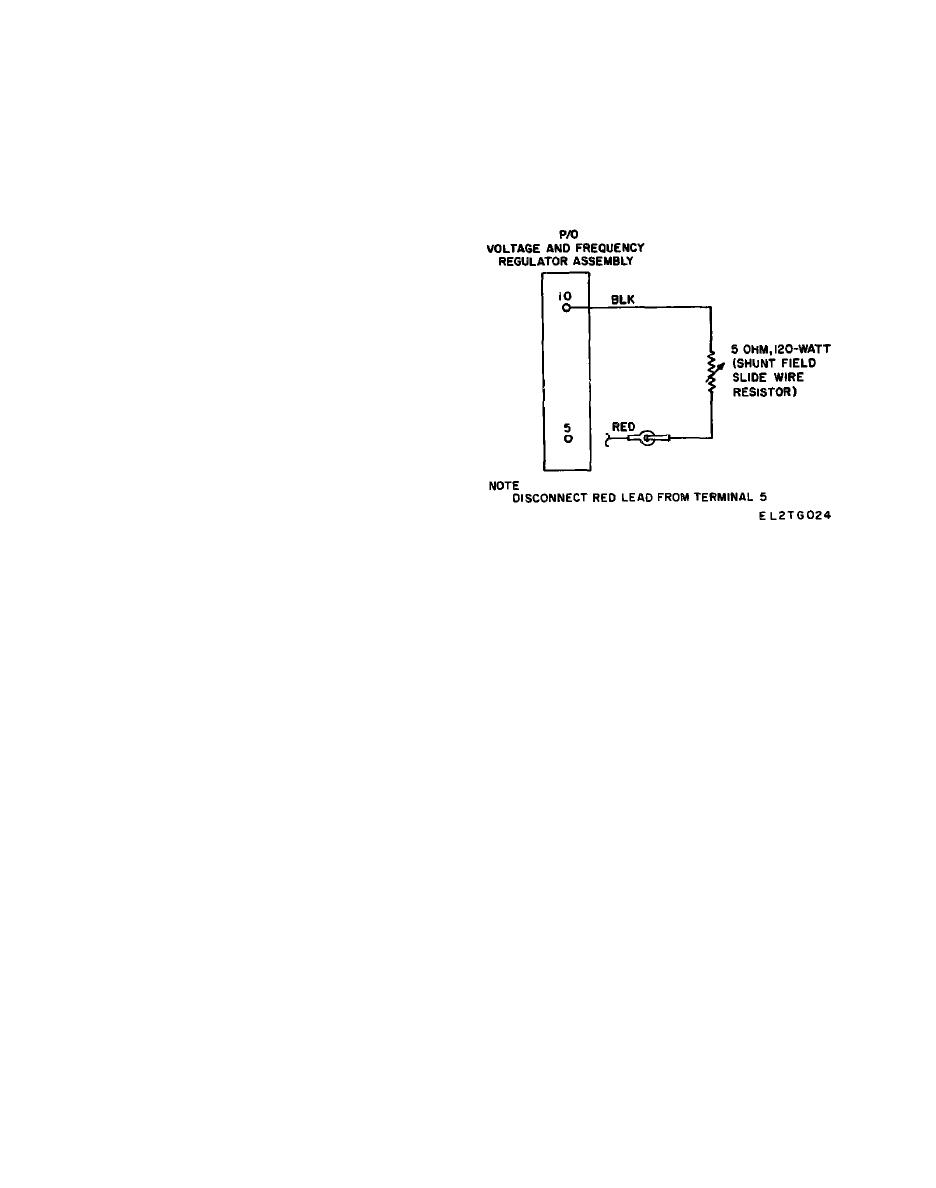

(1) Connect the shunt field slide wire resistor

while observing the phase A to neutral output fre-

as shown in fig 4-3 2

quency and voltage If the output frequency can be

(2) connect terminals 5 and 10 of the voltage and

varied between the limits of 390 and 410 Hz while the

frequency regulator assembly to ground through a 3 0-

ac output remains approximately 116 volts, the fre-

ohm, 300-watt resistor (This resistor will place a shunt

quency regulation circuits are probably operational

field load on the regulator)

However, to prevent an assembly with an intermittent

(3) Reapply the 28-volt dc input and adjust the

problem from being returned to service, subject the

shunt field wire resistor for a 400-Hz output

known good motor-generator with the questionable reg-

ulator assembly to general support commutation and

c Check that the following regulator input voltages

spin tests If these tests are satisfactorily performed, the

are present

assembly may be returned to service If incorrect re-

(1) At least 27 4 volts dc across the armature,

sults are obtained, make troubleshooting voltage meas-

measured at terminal 4 to ground

urements as described in paragraph 4-10 3

(2) 115 to 117 volts ac from terminal 1 to ground

(residual magnetic buildup voltage)

d To ensure that an operational voltage and fre-

Measurements

quency regulator assembly has not been returned for

A pointed probe will be required to puncture the pro-

General Support Maintenance, make the following

tective coating when making voltage checks After re-

check

pairs are completed, this coating must be restored in

(1) Reduce the dc input to 27 5 volts

accordance with paragraph 4-10 5, step e

(2) While observing the phase A to neutral out-

put voltage, rotate the voltage adjust potentiometer (fig

NOTE

3-1) fully counter-clockwise and then fully clockwise

All measurements are to be made with a 28-

If the output voltage can be varied between the limits

volt dc input and a 115-volt 400-Hz ac no-

of 110 and 120 volts, the voltage regulator circuits are

load output

probably operational If the output voltage range is ob-

a Voltage Regulation Circuits Check the voltage

tained, adjust the output to 116 volts and perform step

(3) If the range is not obtained, make troubleshoot-

regulation circuits as follows