TB 11-6115-741-24

3.13.7 On the 5 KW, 28 VDC, APU; replace as required the plastic (fuel line) tee above the

cylinder head with a brass tee, NSN 4730-01-058-9758. This tee is in the fuel return line.

3.15.1 The housing interior and exterior shall be cleaned, repaired and repainted as required; minor dents

that do not affect the serviceability are acceptable. All electrical and mechanical components shall be

inspected and repaired or replaced as required. All wiring shall be cleaned and inspected in-place, then

repaired or replaced as required. Pull on any spliced wires to test physical integrity of splice (s).

Connectors and terminal ends shall be cleaned or replaced if any corrosion is observed. Replacement

wires shall be routed along and neatly attached to the existing harness. The housing shall have a coat of

CARC paint in accordance with MIL-DTL-53072, color/pattern as specified by CECOM.

3.15.2 On the AN/MJQ-32 & -33 switch box P/N 13205E5079, verify that the indicator lights are wired

to A1 and B1 and thus operate in both single- and three-phase operation.

3.15.3 On the AN/MJQ-35/36 & -37/38 switch box P/N 13229E5820, verify that the procedure in

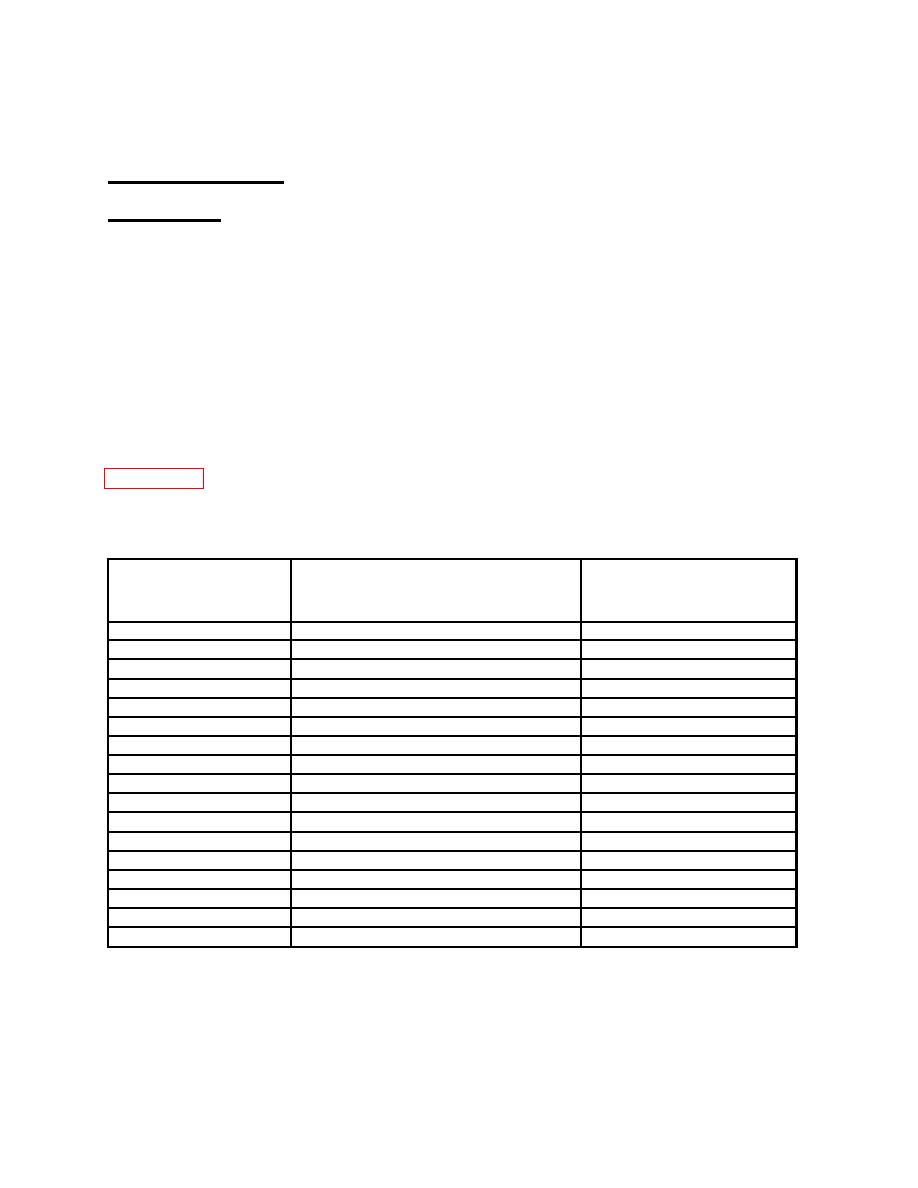

TABLE 5. Used Fuel Injector Opening Pressure

Generator Size

Used Fuel Injector

Opening Pressure

And Type

Model Number

(Nom. Psi)

2 kW MTG

MEP-501A/531A

2700

2700

3 kW TQG

MEP-831A/832A

3481

5 kW TQG

MEP-802A/812A

3481

10 kW TQG

MEP-803/813A

1706

15 kW TQG

MEP-804/814A

3620

30 kW TQG

MEP-805/815A/805B/815B

3620

60 kW TQG

MEP-806A/816A/806B/816B

2700

3 kW Mil Std

MEP-016B/701 Yanmar L100

1750

5 kW Mil Std

MEP-002A

1750

10 kW Mil Std

MEP-003A/112A

2750

15 kW Mil Std

MEP-004A/113A

2750

30 kW Mil Std

MEP-005A/114A

2900

60 kW Mil Std

MEP-006A/115A

615

100 kW Mil Std

MEP-007B

3400

5 kW APU

MEP-952B

1991

10 kW APU

MEP-903A/903B/903C

NOTE:

Used fuel injector opening pressure will vary somewhat from nominal, however, cylinder

to cylinder pressures on an engine should not vary.