TM 9-6115-624-BD

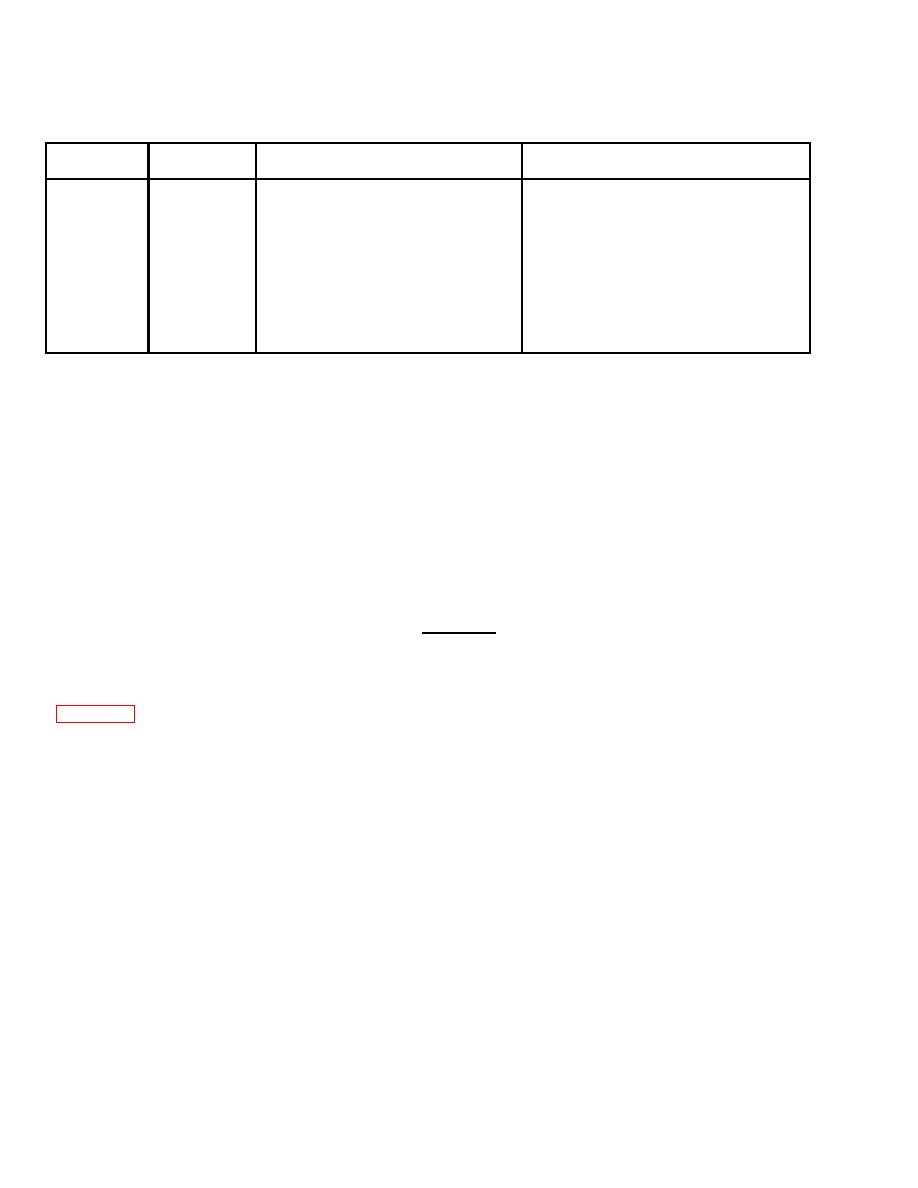

Table B-1. Tools.-CONT.

Item

number

Level

NSN

Description

39

C

5120-00-277-4244

Wrench, plier: straight jaw, 8-1/2 in.

40

C

5120-00-148-7917

Wrench Set, combination box with

open end, 12 components, 5/16

in.-1 in.

41

C

5120-00-148-7918

Wrench Set, open end, fixed, 6

components 3/16 in.-1-1/16 in.

Section III. TEST EQUIPMENT

B-3. Field Expedient Test Equipment . Sometimes, in the process of assessing the battlefield damage, it is necessary

to make voltage and resistance measurements to determine where the fault is. Standard test equipment (voltmeter,

ohmmeter, SWR meter, etc.) should be used whenever possible. If standard test equipment is not available, field

expedient equipment can be fabricated using parts commonly found on the generator and in the forward maintenance

areas. The following paragraph provides fabrication instructions for making a voltmeter, ohmmeter, and RF transmitter

output tester.

NOTE

Accurate measurements are not available. These are Go-No-Go meters.

WARNING

This voltage indicator can only be used safely below 37 volts DC.

a.

Making a Voltage Indicator. A voltage indicator can be made from a light bulb and two pieces of wire

(figure B-1). The pieces of wire can be connected to the case and center terminal of the bulb by means of solder,

twisting, or simply holding the wire ends against the bulb (see illustration). The voltage rating of the bulb should be close

to the value of the expected voltage being tested. For voltages in the 18 to 30V dc range, any light bulb on the driver's

master panel, driver's instrument panel, gunner's panel, commander's panel, or gunner's primary sight can be used. For

voltages of 5V dc or less a two-battery cell flashlight can be used. The presence of voltage will cause the bulb to glow.

Polarity of DC voltage does not have to be observed; even ac voltage can be measured. Twist exposed wire ends

together and I apply solder, if available, and solder. Touch wires to voltage source when ready to test for voltage.

B-4 Change 1